CHECKING MANIFOLD GAS PRESSURE

If it should be necessary to check the manifold

gas pressure, connect manometer (water gauge)

or other pressure device to the top burner orifice

farthest from the manifold inlet and turn burner

valve on. For an accurate pressure check have at

least 2 other top burners burning. Be sure the gas

supply inlet pressure is at least one inch above

specified range manifold pressure. The gas supply

pressure should never be over 14 inches W.C.

When properly adjusted for Natural Gas the W.C.

pressure is 4 inches, for LP Gas the W.C. pressure

is 10 inches. The serial plate, located under the

main top in the burner box area, indicates for

which type of gas your range was factory adjusted.

IF RANGE HAS ELECTRIC

IGNITION—ELECTRICAL CONNECTION

INFORMATION

CAUTION—FOR PERSONAL SAFETY:

DO NOT USE AN EXTENSION CORD

WITH THIS APPLIANCE.

• This appliance must be supplied with the

proper voltage and frequency, and connected to

an individual, properly grounded and polarized

branch circuit, protected by a circuit breaker or

time-delay fuse, as noted on the rating plate.

• Wiring must conform to National Electric

Codes or the prevailing local code for a range of

this kilowatt rating. (See the rating plate under

the cooktop for this information.)

• If the electric supply

provided does not meet

the above specifications,

call a licensed electrician.

6

WARNING

ELECTRICAL GROUNDING

INSTRUCTIONS

This appliance is equipped with a three

prong grounding plug for your protection

against shock hazard and should be

plugged directly into a properly grounded

receptacle. Do not cut or remove the

grounding prong from this plug.

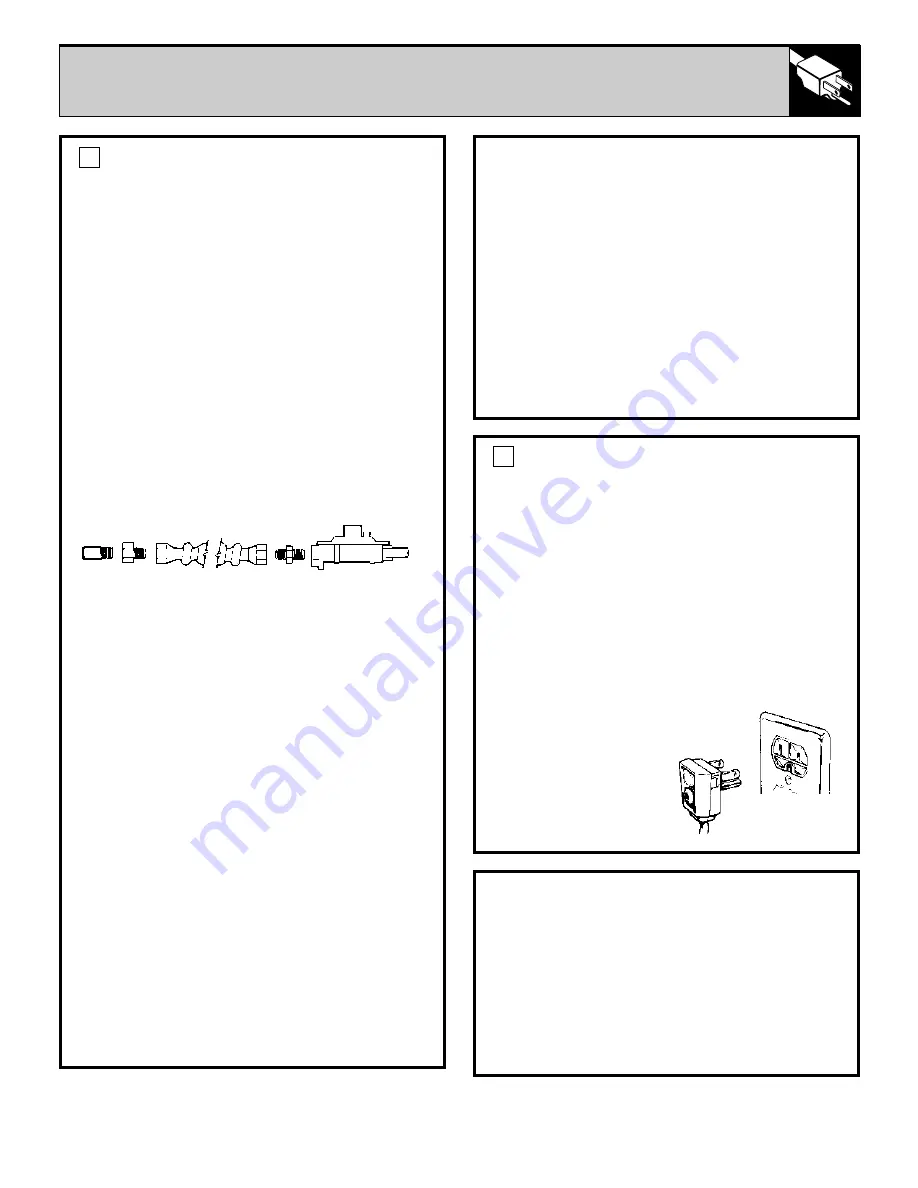

CONNECT THE RANGE TO GAS

1. If the range is to be connected to house

piping with flexible or semi-rigid metal appliance

connector, connector nuts MUST NOT be

connected directly to pipe threads.

2. The appliance connector must be installed by

using the proper flare union adapters with the

connector. Cutoff valve, appliance connector and

adapters are not supplied with the range.

(Because solid pipe restricts moving the range,

we recommend use of A.G.A. certified flexible

tubing.) In Canada, flexible connectors must be

single wall metal connectors no longer than 6

feet in length.

• The house piping and connector used to

connect the range to the main gas supply must

be clean, free of metal shavings, rust, dirt or

liquids (oil or water). Contaminants in the supply

lines can work their way into the range manifold

and cause failure of gas valves or controls and

clog burners or pilot orifices.

3. Install a manual shutoff valve in the gas line in

an easily accessible location outside of the range.

Be sure you know how and where to shut off the

gas supply to the range.

4. Check for leaks. After connecting the range to

gas, check the system for leaks with a liquid leak

detector at all joints and connections.

5. Tighten all connections as necessary to

prevent gas leakage in the range or supply line.

CAUTION: DO NOT USE A FLAME TO

CHECK FOR GAS LEAKS.

6. Check alignment of valves after connecting the

range to the gas supply to be sure the manifold

pipe has not been moved. A misalignment could

cause the valve knob stem to rub on the control

panel, resulting in a gas leak at the valve.

Disconnect the range and its individual shut-off

valve from the gas supply piping system during

any pressure testing of the system at test

pressures greater than 1/2 psig.

Isolate the range from the gas supply piping

system by closing its individual manual shut-off

valve during any pressure testing of the gas

supply piping system at test pressures equal to

or less than 1/2 psig.

5

House

Piping

Flare

Union

Adapter

Flare

Union

Adapter

Nut

Nut

Appliance

Connector

Range Pressure

Regulator

INSURE PROPER

GROUND EXISTS

BEFORE USE.

29

(continued next page)

Summary of Contents for JGAS24

Page 34: ...34 NOTES...