– 35 –

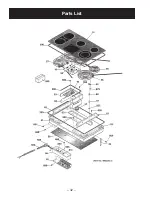

Ref No.

Part No.

Description

Qty.

820

WB01X1424

Screw

2

875

WH02X0930

Screw 8-18 AB HXW 3/8

8

925

WB01K5117

Washer .250IDX.8120D

8

926

WB01X1260

Ground Washer

1

962

WB02T10093

Standoff PCB

10

999

49-80021

Use & Care Manual

1

999

WB18T10162

Power Control Harness

1

999

WB18T10163

Heater Control Harness

1

999

WB18T10164

Logic Control Harness

1

999

WB18T10166

Logic Display Harness

1

999

WB18T10165

Main Wire Harness

1

999

WB64X0093

Glass Cleaner

1

999

31-10429

Instruction Install

1

999

WB50T10040

AASM Kit Flush (JXFMBB)

1

999

31-10034

PM Sheet Mini Manual

1

999

WB06K5036

Razor Blade Scraper

1

Summary of Contents for JP350

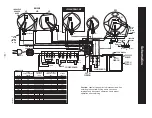

Page 19: ... 17 Fault Code Behavior Table ...

Page 33: ... 31 Notes ...

Page 34: ... 32 Parts List ...

Page 36: ... 34 ...

Page 38: ......

Page 39: ......