GE

D

IRECTION

5573152-100, R

EV

. 2

LOGIQ E9 S

ERVICE

M

ANUAL

9 - 116

Section 9-19 - Options

Section 9-19

Options

For Options Compatible configurations, See:

9-19-1 "Options Compatible Configurations" on page 9-120

Table 9-59 Options 1 of 4

ITEM

PART NAME

PART NUMBER

DESCRIPTION

QTY

FRU

1.

V Nav, Drive Bay 3D Tracking

System Electronics Unit

R3.x and earlier

1

Y

2.

Dr (System Electronics Unit)

R4.x and Later

1

Y

3.

V Nav, Drive Bay 3D Tracking System

Single 8mm Sensor Assembly

5168286-25

Replaced by 5168286-30

2

Y

4.

V Nav, Drive Bay 3D Tracking System

Dual 8mm Sensor Assembly

5168286-30

2

Y

5.

eTRAX Needle Sensor Spare Part

(Needle Tracking Option)

R2.0.5 or later

5408134

6.

VirtuTRAX Sensor Spare Part

(Virtual Tracking Option)

R2.0.5 or later

5416625

7.

V Nav, Drive Bay 3D Tracking System Mid

Range Transmitter Assembly

for DriveBay 2 only

5457453

1

Y

8.

Drive Bay 2 Flat Transmitter

5437445

1

Y

9.

driveBAY 3D Tracking System Mid Range

Transmitter

5168286-45

1

Y

10.

Cable, V Nav, Baybird Power

Cable Y, See:

Table 9-57 - Peripherals Cables

11.

Cable, V Nav, USB BEP to BayBird

Cable Z, See:

Table 9-57 - Peripherals Cables

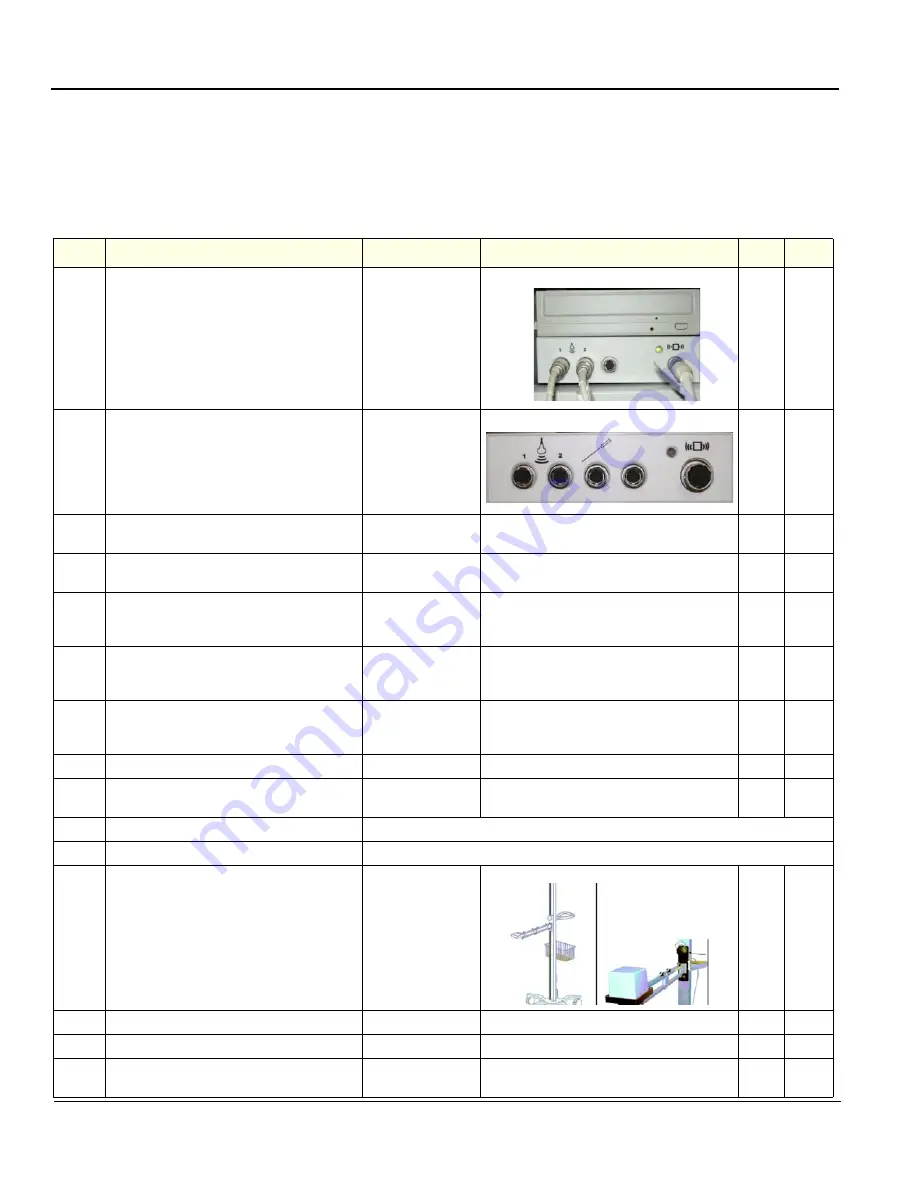

12.

Stand for Tru3D Transmitter

1

Y

13.

V Nav Transmitter Stand Handles

5268740-30

1

Y

14.

V Nav Transmitter Stand Arm

5268740-10

1

Y

15.

V Nav Transmitter Stand Wheels

(set of 5)

5268740-20

1

Y

Summary of Contents for LOGIQ E9

Page 2: ......

Page 11: ...GE DIRECTION 5573152 100 REV 2 LOGIQ E9 SERVICE MANUAL xi ZH CN KO ...

Page 753: ......

Page 754: ......