26

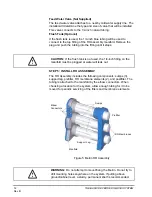

DIMENSIONS

Rev B

SPECIFIC CONTAMINANT PERFORMANCE

Testing performed under standard laboratory conditions. Actual results may vary.

Contaminant

Influent (avg.

mg/L)

Effluent (ave.

mg/L)

Effluent (max.

mg/L)

Ave %

Reduction

Arsenic

a

a. This system has been tested for the treatment of water containing pentavalent arsenic (also known as As(V),

As(+5), or arsenate) at concentrations of 0.050 mg/L or less. This system reduces pentavalent arsenic, but

may not remove other forms of arsenic. This system is to be used on water supplies containing a detectable

free-chlorine residual at the system inlet or on water supplies that have been demonstrated to contain only

pentavalent arsenic. Treatment with chloramines (combined chlorine) is not sufficient to ensure complete

conversion of trivalent arsenic to pentavalent arsenic. Please see the Arsenic Facts section of the Merlin

system performance data sheet.

0.049

0.00265

0.00612

94.6%

Barium

11.1

0.189

1.9

98.3%

Cadmium

0.0307

0.0000704

0.0000704

99.8%

Chromium (VI)

0.353

0.00742

0.0147

97.9%

Chromium (III)

0.312

0.000624

0.00453

99.8%

Copper

3.22

0.0721

0.0721

97.8%

Fluoride

8.11

0.51

0.65

93.7%

Lead

0.159

0.000628

0.000628

99.6%

Nitrate/Nitrite (as N)

b

b. This system is acceptable for treatment of influent concentrations of no more than 27 mg/L nitrate and 3 mg/L

nitrite in combination measured as N and is certified for nitrate/nitrite reduction only for water supplies with a

pressure of 40 psi (2.76 bar) or greater.

To verify the level of nitrate/nitrite in the product water use the test strips that have been included with the

system. Follow the instrucions that are on the test strip packaging.

The level of nitrate/nitrite in the product water should be within local standards before placing the Merlin system

into operation.

28.96

6.26

7.55

78.4%

Radium 226/228

Selenium

0.113

0.00249

0.003

97.8%

Total Dissolved Solids (TDS)

726

74.8

94.8

89.7%

Summary of Contents for MERLIN 1255052

Page 20: ...20 APPENDIX Rev B APPENDIX...

Page 25: ...DIMENSIONS 25 Rev B...