(due to retries), increasing message error counts, erratic communications, and in the worst case, complete

failure to communicate.

3.2.1

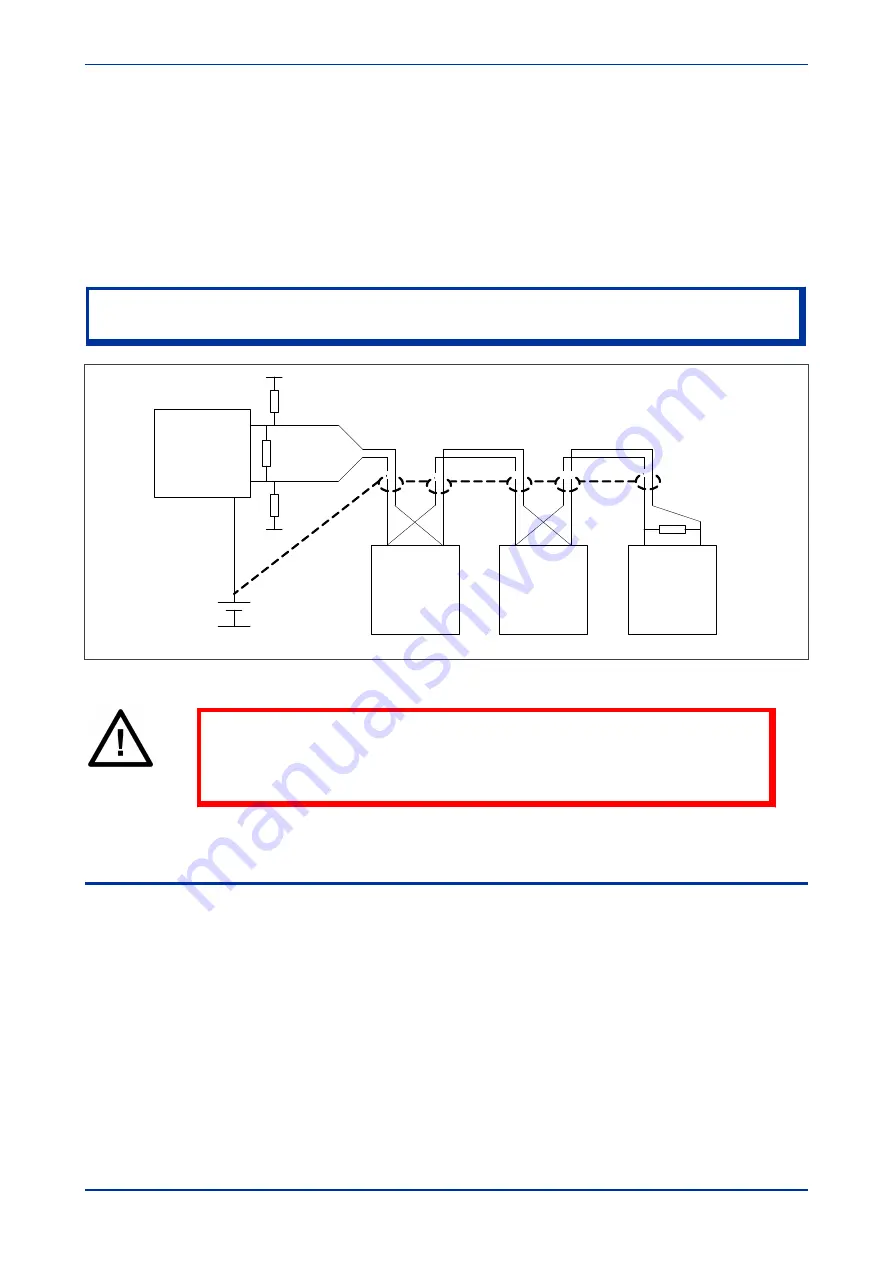

EIA(RS)485 BIASING REQUIREMENTS

Biasing requires that the signal lines be weakly pulled to a defined voltage level of about 1 V. There should

only be one bias point on the bus, which is best situated at the master connection point. The DC source used

for the bias must be clean to prevent noise being injected.

Note:

Some devices may be able to provide the bus bias, in which case external components would not be required.

V01000

Master

6 – 9 V DC

0 V

120 Ω

180 Ω bias

180 Ω bias

Slave

Slave

Slave

120 Ω

Figure 47: RS485 biasing circuit

Warning:

It is extremely important that the 120 Ω termination resistors are fitted.

Otherwise the bias voltage may be excessive and may damage the devices

connected to the bus.

It is possible to use the product’s field voltage output (48 V DC) to bias the bus using values of 2.2 kΩ 0.5 W

bias resistors instead of the 180 Ω resistors shown in the above diagram. If using the field voltage, please

heed the following warnings.

3.3

K-BUS

K-Bus is a robust signalling method based on RS485 voltage levels. K-Bus incorporates message framing,

based on a 64 kbps synchronous HDLC protocol with FM0 modulation to increase speed and security.

The rear interface is used to provide a permanent connection for K-Bus, which allows multi-drop connection.

A K-Bus spur consists of up to 32 IEDs connected together in a multi-drop arrangement using twisted pair

wiring. The K-Bus twisted pair connection is non-polarised.

Two-core screened twisted pair cable should be used. The final cable specification is dependent on the

application, although a multi-strand 0.5 mm

2

per core is normally adequate. The total cable length must not

exceed 1000 m. It is important to avoid circulating currents, which can cause noise and interference,

especially when the cable runs between buildings. For this reason, the screen should be continuous and

connected to ground at one end only, normally at the master connection point.

Chapter 7 - SCADA Communications

MiCOM P747

196

P747-TM-EN-1

P747-TM-EN-1.1

Summary of Contents for MiCOM P747 Agile

Page 2: ......

Page 16: ...Contents MiCOM P747 xiv P747 TM EN 1 P747 TM EN 1 1...

Page 20: ...Table of Figures MiCOM P747 xviii P747 TM EN 1 P747 TM EN 1 1...

Page 21: ...INTRODUCTION CHAPTER 1...

Page 22: ...Chapter 1 Introduction MiCOM P747 2 P747 TM EN 1 P747 TM EN 1 1...

Page 31: ...SAFETY INFORMATION CHAPTER 2...

Page 32: ...Chapter 2 Safety Information MiCOM P747 12 P747 TM EN 1 P747 TM EN 1 1...

Page 42: ...Chapter 2 Safety Information MiCOM P747 22 P747 TM EN 1 P747 TM EN 1 1...

Page 43: ...HARDWARE DESIGN CHAPTER 3...

Page 44: ...Chapter 3 Hardware Design MiCOM P747 24 P747 TM EN 1 P747 TM EN 1 1...

Page 74: ...Chapter 3 Hardware Design MiCOM P747 54 P747 TM EN 1 P747 TM EN 1 1...

Page 75: ...CONFIGURATION CHAPTER 4...

Page 76: ...Chapter 4 Configuration MiCOM P747 56 P747 TM EN 1 P747 TM EN 1 1...

Page 117: ...PROTECTION FUNCTIONS CHAPTER 5...

Page 118: ...Chapter 5 Protection Functions MiCOM P747 98 P747 TM EN 1 P747 TM EN 1 1...

Page 160: ...Chapter 5 Protection Functions MiCOM P747 140 P747 TM EN 1 P747 TM EN 1 1...

Page 161: ...MONITORING AND CONTROL CHAPTER 6...

Page 162: ...Chapter 6 Monitoring and Control MiCOM P747 142 P747 TM EN 1 P747 TM EN 1 1...

Page 211: ...SCADA COMMUNICATIONS CHAPTER 7...

Page 212: ...Chapter 7 SCADA Communications MiCOM P747 192 P747 TM EN 1 P747 TM EN 1 1...

Page 259: ...REDUNDANT ETHERNET CHAPTER 8...

Page 260: ...Chapter 8 Redundant Ethernet MiCOM P747 240 P747 TM EN 1 P747 TM EN 1 1...

Page 293: ...CYBER SECURITY CHAPTER 9...

Page 294: ...Chapter 9 Cyber Security MiCOM P747 274 P747 TM EN 1 P747 TM EN 1 1...

Page 313: ...SETTINGS APPLICATION SOFTWARE CHAPTER 10...

Page 314: ...Chapter 10 Settings Application Software MiCOM P747 294 P747 TM EN 1 P747 TM EN 1 1...

Page 322: ...Chapter 10 Settings Application Software MiCOM P747 302 P747 TM EN 1 P747 TM EN 1 1...

Page 323: ...BUSBAR COMMISSIONING TOOL CHAPTER 11...

Page 324: ...Chapter 11 Busbar Commissioning Tool MiCOM P747 304 P747 TM EN 1 P747 TM EN 1 1...

Page 330: ...Chapter 11 Busbar Commissioning Tool MiCOM P747 310 P747 TM EN 1 P747 TM EN 1 1...

Page 331: ...SCHEME LOGIC CHAPTER 12...

Page 332: ...Chapter 12 Scheme Logic MiCOM P747 312 P747 TM EN 1 P747 TM EN 1 1...

Page 348: ...Chapter 12 Scheme Logic MiCOM P747 328 P747 TM EN 1 P747 TM EN 1 1...

Page 349: ...INSTALLATION CHAPTER 13...

Page 350: ...Chapter 13 Installation MiCOM P747 330 P747 TM EN 1 P747 TM EN 1 1...

Page 361: ...COMMISSIONING INSTRUCTIONS CHAPTER 14...

Page 362: ...Chapter 14 Commissioning Instructions MiCOM P747 342 P747 TM EN 1 P747 TM EN 1 1...

Page 387: ...MAINTENANCE AND TROUBLESHOOTING CHAPTER 15...

Page 388: ...Chapter 15 Maintenance and Troubleshooting MiCOM P747 368 P747 TM EN 1 P747 TM EN 1 1...

Page 403: ...TECHNICAL SPECIFICATIONS CHAPTER 16...

Page 404: ...Chapter 16 Technical Specifications MiCOM P747 384 P747 TM EN 1 P747 TM EN 1 1...

Page 425: ...SYMBOLS AND GLOSSARY APPENDIX A...

Page 426: ...Appendix A Symbols and Glossary MiCOM P747 406 P747 TM EN 1 P747 TM EN 1 1...

Page 443: ...COMMISSIONING RECORD APPENDIX B...

Page 444: ...Appendix B Commissioning Record MiCOM P747 424 P747 TM EN 1 P747 TM EN 1 1...

Page 449: ...WIRING DIAGRAMS APPENDIX C...

Page 450: ...Appendix C Wiring Diagrams MiCOM P747 430 P747 TM EN 1 P747 TM EN 1 1...

Page 456: ...Appendix C Wiring Diagrams MiCOM P747 436 P747 TM EN 1 P747 TM EN 1 1...

Page 457: ......