– 19 –

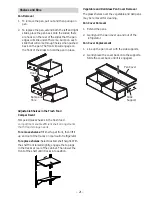

The main freezer drawer slide assemblies are

attached to the drawer front, and are mounted to

the sides of the freezer interior with three T20 Torx

screws per side. The slide must be extended to

expose the front screw. The center and rear holes

are slotted for adjustment to obtain proper sealing

of the drawer gasket to the cabinet frame. It is

not necessary to remove the slides to remove the

evaporator cover.

The upper freezer drawer slide assemblies are

mounted just above the main slides to the sides

of the freezer interior with three Phillips screws per

side. The slide must be extended to expose the front

and middle screws. It is not necessary to remove the

slides to remove the evaporator cover.

Main Drawer Slides

Upper Drawer Slides