9

Installation

36" Stainless Steel Refrigerators, Freezers

• A cold water supply is required for automatic

icemaker operation. The water pressure must be

between 20 and 120 p.s.i.

• Route 1/4" OD copper or GE SmartConnect

™

tubing

between house cold water line and the water

connection location.

• Tubing should be long enough to extend to the front

of the freezer. Allow enough to accommodate bend

leading into the water valve.

NOTE:

The only GE approved plastic tubing is supplied

in the GE SmartConnect

™

Refrigerator Tubing Kits.

Do not use any other plastic water supply line because

the line is under pressure at all times. Other types of

plastic may crack or rupture with age and cause water

damage to your home.

GE SmartConnect

™

Refrigerator Tubing Kits are

available in the following lengths:

2' (0.6 m) WX08X10002

6' (1.8 m) WX08X10006

15' (4.6 m) WX08X10015

25' (7.6 m) WX08X10025

Shut off the main water supply

Turn on the nearest faucet long enough to clear the line

of water.

Install a shut-off valve between the icemaker water

valve and cold water pipe in a basement or cabinet.

The shut-off valve should be located where it will be

easily accessible.

NOTE:

Saddle type shut-off valves are included in many

water supply kits. Before purchasing, make sure a saddle

type valve complies with your local plumbing codes.

• Install optional water filter in the water line near the

freezer. A water filter is recommended in areas where

water supply contains sand or particles. Installation

instructions are packed with the filter.

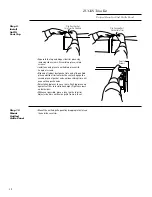

Step 2

Install

Freezer

Water Line

NOTE:

Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves are

illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

Floor

Tubing