Summary of Contents for MULTILIN 269 MOTOR MANAGEMENT RELAY Series

Page 3: ...TABLE OF CONTENTS ii GLOSSARY ...

Page 11: ...2 INSTALLATION 2 2 Figure 2 2a Phase CT Dimensions ...

Page 12: ...2 INSTALLATION 2 3 Figure 2 2b Ground CT 50 0 025 3 and 5 window ...

Page 13: ...2 INSTALLATION 2 4 Figure 2 2c Ground CT 50 0 025 8 window ...

Page 14: ...2 INSTALLATION 2 5 Figure 2 2d Ground CT x 5 Dimensions ...

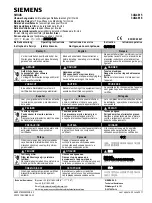

Page 17: ...2 INSTALLATION 2 8 Figure 2 4 Relay Wiring Diagram AC Control Power ...

Page 19: ...2 INSTALLATION 2 10 Figure 2 6 Relay Wiring Diagram Two Phase CTs ...

Page 20: ...2 INSTALLATION 2 11 Figure 2 7 Relay Wiring Diagram DC Control Power ...

Page 29: ...2 INSTALLATION 2 20 Figure 2 11 269 Drawout Relay Physical Dimensions ...

Page 30: ...2 INSTALLATION 2 21 Figure 2 12 269 Drawout Relay Mounting ...

Page 31: ...2 INSTALLATION 2 22 Figure 2 13 269 Drawout Relay Typical Wiring Diagram ...

Page 34: ...2 INSTALLATION 2 25 Figure 2 16 MPM Mounting Dimensions ...

Page 35: ...2 INSTALLATION 2 26 Figure 2 17 MPM to 269 Typical Wiring 4 wire Wye 3 VTs ...

Page 36: ...2 INSTALLATION 2 27 Figure 2 18 MPM to 269 Typical Wiring 4 wire Wye 2 VTs ...

Page 37: ...2 INSTALLATION 2 28 Figure 2 19 MPM to 269 Typical Wiring 3 wire Delta 2 VTs ...

Page 38: ...2 INSTALLATION 2 29 Figure 2 20 MPM to 269 Typical Wiring 2 CT ...

Page 39: ...2 INSTALLATION 2 30 Figure 2 21 MPM Wiring Open Delta ...

Page 40: ...3 SETUP AND USE 3 1 Figure 3 1 Front Panel Controls and Indicators ...

Page 86: ...3 SETUP AND USE 3 47 Figure 3 2 Wiring Diagram for Contactors ...

Page 87: ...3 SETUP AND USE 3 48 Figure 3 3 Wiring Diagram for Breakers ...

Page 93: ...3 SETUP AND USE 3 54 Figure 3 5 Standard Overload Curves ...

Page 102: ...4 RELAY TESTING 4 2 Figure 4 1 Secondary Injection Test Set AC Input to 269 Relay ...

Page 103: ...4 RELAY TESTING 4 3 Figure 4 2 Secondary Injection Test Set DC Input to 269 Relay ...

Page 106: ...4 RELAY TESTING 4 6 Figure 4 3 Hi Pot Testing ...

Page 108: ...5 THEORY OF OPERATION 5 2 Figure 5 1 Hardware Block Diagram ...

Page 110: ...5 THEORY OF OPERATION 5 4 Figure 5 2 Firmware Block Diagram ...

Page 112: ...6 APPLICATION EXAMPLES 6 2 Figure 6 1 Thermal Limit Curves ...

Page 126: ...APPENDIX H H 3 Figure H 1 Excitation Curves Figure H 2 Excitation Curves Method ...

Page 133: ......

Page 137: ......

Page 139: ......

Page 141: ......

Page 142: ......