Protection Schemes

745

Transformer Management Relay

Commission

ing

http://www.GEindustrial.com/multilin

7–11

GE Multilin

Analog Outputs

1. The analog output settings are located in the

S2 SYSTEM SETUP

!"

ANALOG OUT-

PUTS

setpoints section.

2. Connect a milliammeter to the Analog Output contacts: COM on A5 and Analog

Output 1 on A6, Analog Output 2 on A7, Analog Output 3 on A8, Analog Output

4 on A9, Analog Output 5 on A10, Analog Output 6 on A11, or Analog Output 7

on A12.

3. From the settings used for the tested Analog output, determine the mA range

for the output and the driving signal and its range for the full range of output

current.

4. Apply the input signal and vary its amplitude over the full range and ensure the

Analog Output current is the correct amplitude. Record the results in the table

below. Duplicate as required for each Analog Output.

Tap Position

1. The Analog Input used to sense tap position is programmed with the

S2 SYSTEM

SETUP

!"

ONLOAD TAP CHANGER

setpoints.

2. To verify the operation of this circuit, connect a variable resistor across

terminals A3 and A4. The resistor range should cover the full range of resistance

produced by the tap changer mechanism. The tap position is displayed in

A2

METERING

!"

TAP CHANGER

!

TAP CHANGER POSITION

.

3. Adjust the resistance to simulate the minimum tap position and verify that a “1”

is displayed. Now gradually increase the resistance up to the value which

represents the maximum tap value, verifying that the tap position indicator

tracks the resistance.

Protection Schemes

Precautions

Keep track of modifications/changes made to settings during the

course of these commissioning steps and ensure that all settings are

returned to the ‘in-service’ values at the end of the tests.

Harmonic Restrained

Percent Differential

a) Description

The harmonic restrained percent differential element setpoints are located in

S4

ELEMENTS

!"

DIFFERENTIAL

!

PERCENT DIFFERENTIAL

. Disable all other protection

elements to ensure that trip relay(s) and auxiliary relays are operated by element

under test only. With a multimeter, monitor the appropriate output contact(s) per

intended settings of the FlexLogic™. Refer to the relay settings to find out which

relay(s) should operate when a given element operates.

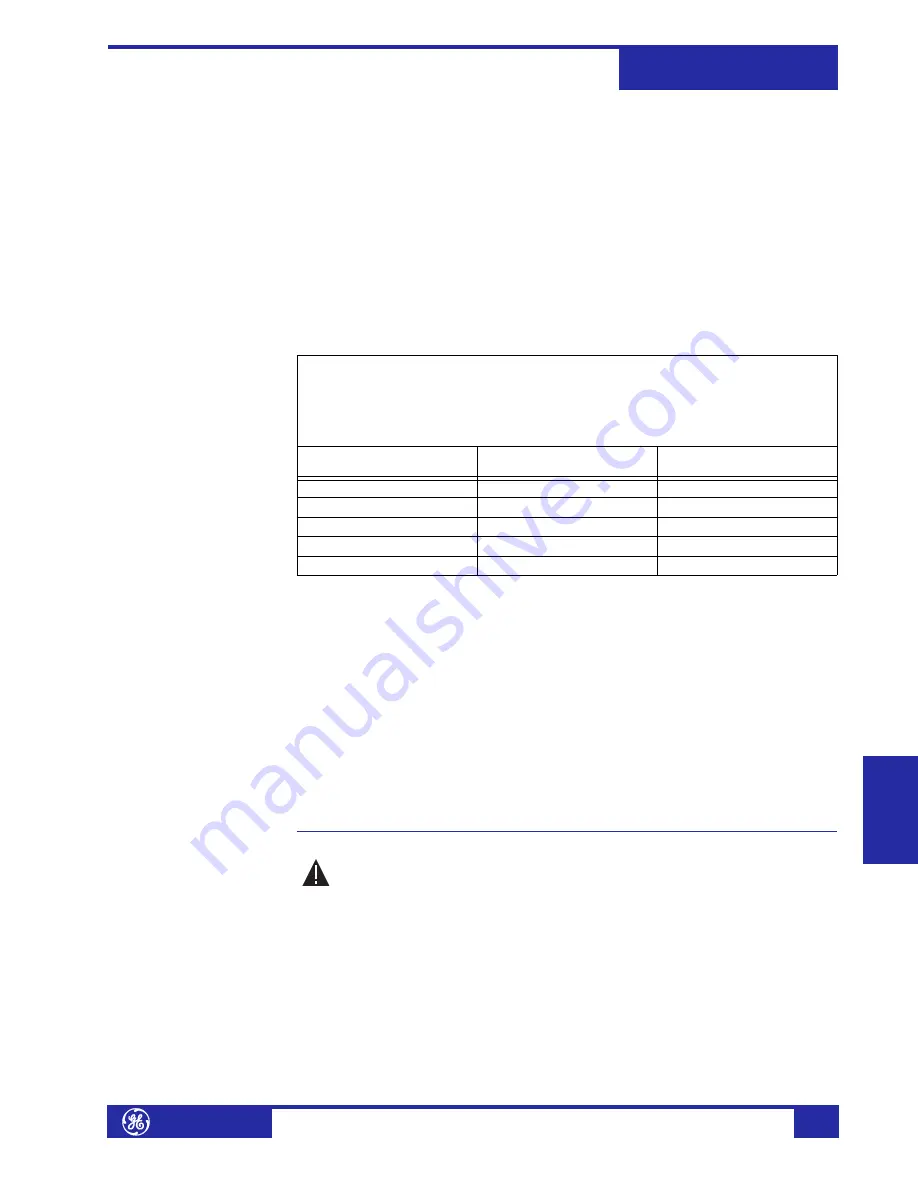

Table 7–2: Analog Output Calibration Results

Analog Output Number: __________

Analog Output Min.: ______________

Analog Output Value: ___________

Analog Output Max.: ___________

Analog Output Range: ____________

Input Signal Amplitude

(% of full range)

Expected mA Output

Measured mA Output

0

25

50

75

100

CAUTION

Summary of Contents for Multilin 745

Page 2: ......