GEI-56128H

10

10. Space heaters should be de-energized

during motor operation.

11. Check the operating current against the

nameplate value. Do not exceed the value of

nameplate current multiplied by the motor service

factor (if any) under steady continuous load.

C. Jogging and Repeated Starts

CAUTION

:

Repeated starts and/or jogs of

induction motors greatly reduce the life of

the winding insulation.

The heat produced by each acceleration or jog is

much more than that dissipated by the motor

under full load. If it is necessary to repeatedly start

or jog a motor, it is advisable to check the

application with the local GE Energy sales office.

V.

MAINTENANCE

WARNING

:

Before

initiating

maintenance procedures, disconnect

all power sources to the motor and

accessories. For motors equipped with surge

capacitors, do not handle the capacitors until they

are discharged by a conductor simultaneously

touching all terminals and leads, including earth.

This discharge conductor should be insulated for

handling. Replace all normal grounding

connections prior to operating

.

A.

General

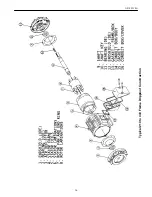

If the motor is dismantled during maintenance, sealing

compounds (if any) shall be removed from machined

rabbets (spigots). When reassembling the motor, all

machined surfaces forming metal-to-metal joints

should be sealed with watertight sealing compound

(Tite-Seal, GE Spec. A50CD427A or equivalent)

.

Inspect the motor at regular intervals, depending on

service. Keep the motor clean and the ventilation

openings clear.

In addition to the daily observation of the overall

condition, it is recommended that a general inspection

routine be set up to check periodically the following

items:

1. General cleanliness

2. Insulation and windings

3. Lubrication and bearings

B. General Cleanliness

The interior and exterior of the motor should be kept

free from dirt, oil and grease and conducting dust.

Paper, textile or dusts may build up and block off

ventilation. Any of these contaminants can lead to

early motor failure.

C.

Division 1 Explosion Proof Motors

Division 1 Explosion-proof motors have special

features and are manufactured in accordance with UL

and carry its label. Therefore, repairs need to be made

at a GE Service Shop, which has been authorized to

make such repairs.

D. Insulation and Windings

To obtain a long life and satisfactory operation of

insulated windings, they should be kept clean from dirt,

oil, metal particles and other contaminants. A variety

of satisfactory and acceptable methods are available

for keeping the windings clean. The choice of method

will depend greatly on time, availability of equipment

and on the insulation system. Vacuum and/or

compressed air cleaning with non-metallic hose tips

should precede cleaning with water and detergent or

with solvents. Tightly adhering dirt will require removal

by gentle brushing or wiping.

WARNING:

To prevent injury to the eyes

and respiratory organs, safety glasses

and suitable ventilation or other

protective equipment should be used.

E. Vacuum and Compressed

Air Cleaning

Compressed air should be used to remove loose dirt

and dust from air passages such as air ducts. Suction

should be used to remove dirt from the windings and

to avoid damaging the coils.

CAUTION:

Care must be taken to make

sure the air is dry and that air pressure of

not more than 21 x 10

3

kg/m

2

(30 psi)

is used.

WARNING:

Operator must not use

compressed air to remove dirt or dust

from his person or clothing

.