GEI-56128H

13

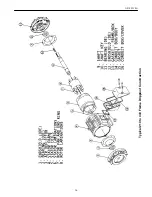

(2) Inspect the journals and polish

them with crocus clothe if any scratches are detected.

Do not allow any metal dust to fall into the housing

when polishing the journals.

(3) Spread a thin coat of oil over

the journal and bearing surfaces before reassembling.

(4) The sealing surfaces of the

bearing should be coated with a sealing compound

such as No. 3 Permatex.

(5) To replace the bearing, reverse

the disassembly procedure.

VI.

OPERATIONAL DIFFICULTIES

Some operating difficulties may occur. Common causes are given in Table 2 and should be corrected as soon as

possible.

TROUBLE SHOOTING CHART

Table 2

Affected Parts

Difficulty

What to Check

Windings

Overheating

•

Calibration of measuring instrument

•

Excessive Current

•

Unbalanced AC current

•

Improper or restricted ventilation

•

Excessive ambient temperature

•

Short circuited coil or windings

•

Dirty windings

•

Unbalanced voltage

Bearings

Overheating

•

Calibration of measuring instrument

•

Worn out or dirty oil *

•

Rough journal *

•

Oil rings jammed *

•

Insufficient Oil *

•

Misalignment

•

Excessive end thrust or radial loading

•

Shaft currents

•

Excessive or insufficient grease **

•

Worn out or dirty grease **

Motor

Excessive Vibration

•

Unbalance

•

Misalignment

•

Improper or settled foundation

•

Non-uniform air gap

•

Rubbing parts

•

Bent shaft

•

Unbalanced stator current

•

Damaged bearing

Winding Insulation

Low insulation resistance

or insulation failure

•

Moisture, dirt, metal particles, oil, or other contaminants on

the windings

•

Wrong voltage

•

Excessive temperature

•

Voltage surges

•

Mechanical damage

•

Excessive vibration with resultant mechanical damage

*

Sleeve bearings

**

Anti-friction bearings