GEI-56128H

8

3. For base assembly and motor

mounting, the mounting bolts must be tightened to

prevent changes in alignment and possible damage to

the equipment. It is recommended that a washer be

used under each nut or bolt head to get a secure hold

on the motor feet. As an alternative, flanged nuts or

bolts may be used. The recommended tightening

torques for medium carbon steel mounting bolts, SAE

Grade 5, are listed below in

Table 1

. For recommended

tightening torques of other hardware on the motor see

tables 4A, and 4B in the Tightening Torque section of

this book.

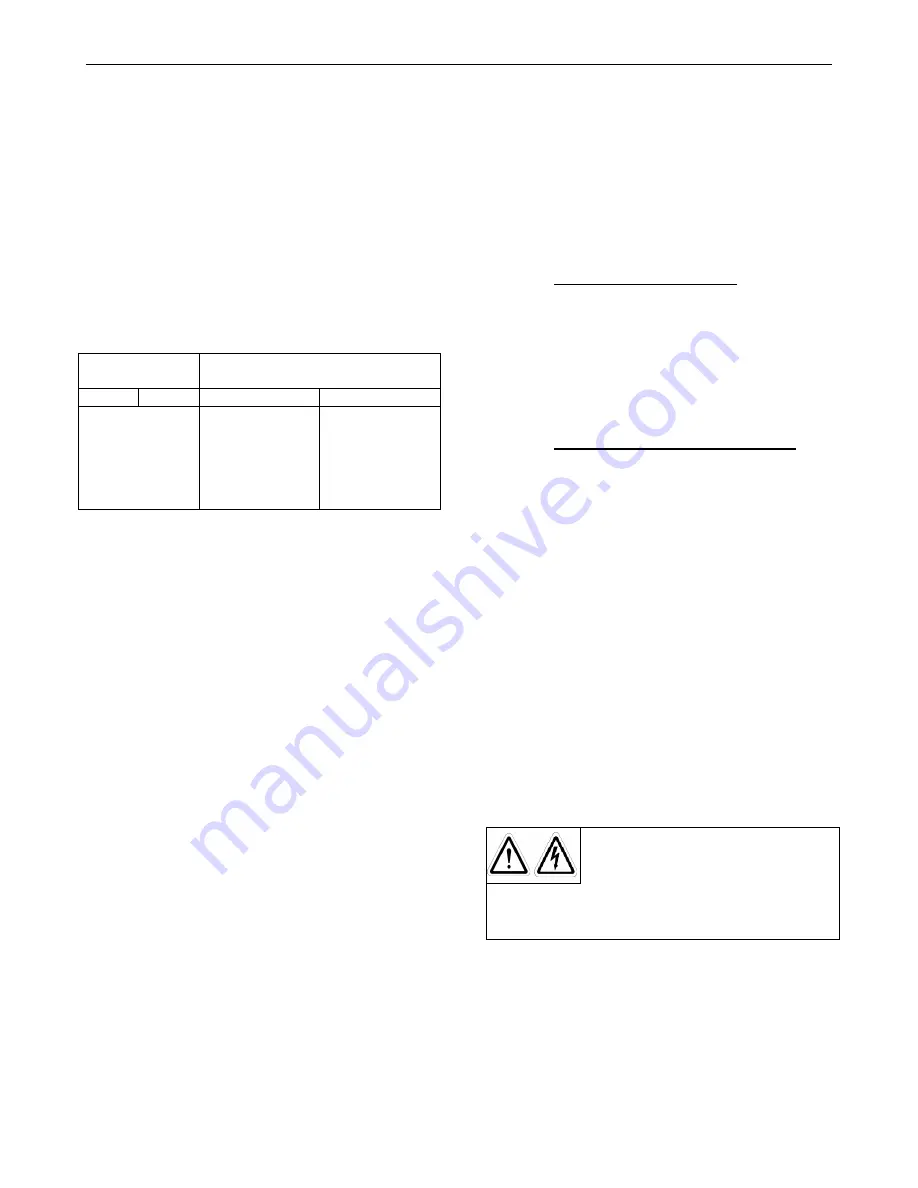

Table 1

Bolt Size

Recommended Torque

in Ft-Lb (N-M)

Inch

Metric

Minimum

Maximum

1/4

(M6)

7

(9)

11

(15)

5/16

(M8)

14

(19)

21

(28)

3/8

(M10)

25

(34)

37

(50)

1/2

(M12)

60

(81)

90

(122)

5/8

(M16)

120

(163)

180

(244)

3/4

(M20)

210

(285)

320

(433)

Note:

For low carbon steel bolts, use 50% of the above

recommended tightening torques. There are no ID

marks on low carbon steel bolts.

4

. For direct coupled applications use

flexible couplings if possible.

Accurate mechanical lineup is essential for successful

operation. Mechanical vibration and roughness in

running the motor may be an indication of poor

alignment. In general, lineup by straight edge across,

and feeler gauges between coupling halves is not

sufficiently accurate. It is recommended that the

lineup be checked with a dial indictor and checking

bars connected to the motor and load-machine shafts.

The space between coupling hubs should be

maintained as recommended by the coupling

manufacturer. Shaft offset should not exceed 0.002”.

Angular misalignment should be less than 0.002”.

4. The application of pulleys, sheaves,

sprockets, and gears on the motor’s shaft is shown in

NEMA Standard MG1-14.07. The application of the V-

belts dimensions for alternating current motors is in

MG1-14.42. V-belt sheave pitch diameters should not

be less than the values shown in Table 14-1 of NEMA

MG-1. Sheave ratios greater than 5:1 and center-to-

center distances less than the diameter of the large

sheave should be referred to the Company. Make

certain that the minimum allowed diameter of the

motor pulley and the maximum belt tension are not

exceed because an excessive pull may cause bearing

trouble and shaft failures. Tighten belts only enough to

prevent slippage. Belt speeds should not exceed 5000

feet per minute (25 meters per second). When V-belts

are used, sheave ratios greater than 5:1 and center-to-

center distances less than the large sheave shall not be

used. The dimensions of the belt pulley are to be

determined according to the kind of belt, transmission

and capacity to be transmitted. Vent holes have to be

kept free and required minimum distances are to be

observed in order not to obstruct the flow of cooling

air. In addition, make sure that the discharged hot air

is not re-circulated into the motor.

C. Sleeve Bearing Endplay

On sleeve-bearing motors, the feet should be

located at a correct distance from the load so that the

motor’s rotor is in the approximate mid-point of its

endplay. The mid-position of the rotor’s endplay is

indicated with a mark on the motor’s shaft. Locate this

mark flush with the bearing housing.

D. Power Supply and Connections

1. Nameplate voltage and frequency

should agree with the power supply. Motors will

operate satisfactorily on line voltage within ±10% of

the nameplate value or frequency within ±5%,

combined variation not to exceed ±10%.

2. Dual voltage motors can be connected

for the desired voltage using instructions on the

nameplate or the connection diagram.

3. Wiring of motor, control, overload

protection and grounding should meet the National

and Local codes.

4. When mounting conditions permit, the

conduit box may be rotated so that the conduit

entrance can be made upward, downward, or from

either side. For oversize conduit boxes, the mounting

height of the motor may have to be increased for

accessibility.

WARNING

:

Motor and control

overload protection and grounding

should be in accordance with the

‘USA -National Electric Code’ or ‘BS/EN 60204-1’

and/or ‘BS/EN 60204-11’ and consistent with sound

local practices

.