Chapter 3. Application System Architecture

8

PACSystems* RX3i Genius Dual Bus Application Guide

GFK-2928

3.1

PROFINET Network Arrangement

A ring topology using MRP is the preferred arrangement. With this topology, a system may use a combination

of PROFINET System Redundancy (PNSR) devices and non-PNSR devices (specifically Genius Communication

Gateway modules).

Also, systems may incorporate managed network switches that support MRP. The approach is particularly

useful for large systems that are upgraded incrementally. In this case, Genius dual busses (each consisting of

four GCG modules

–

Primary A & B, Secondary A & B) may be grouped into one of multiple subrings.

3.2

System and Dual Bus References

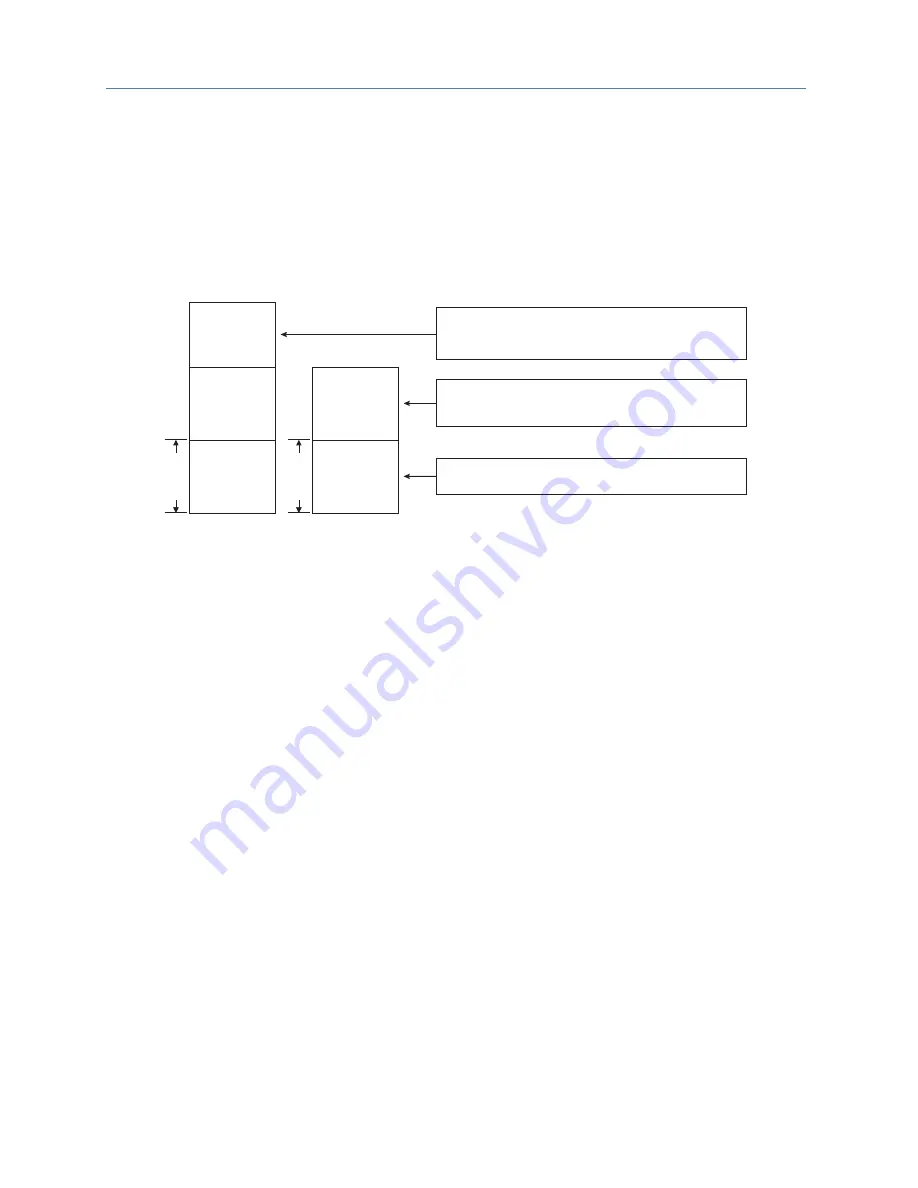

Appl. Refs

%I Addresses

Bus A

(1..8192)

App. Refs.

%AI Addresses

Bus A

(1..8192)

Hardware Status

Addresses

(16385..32767)

Input addresses for the Backup Bus B. The addresses are

offset by the constant DI_OFST (for Discrete Inputs) or

AI_OFST (for Analog Inputs)

These addresses are used by certain types of modules to

display status, diagnostics, etc. Typical modules are CPU,

Ethernet, Serial Communications, Genius bus controllers,

Genius Communications Gateway, Profinet controller, etc.

Input addresses for Bus A. These are the principal references

used in the application’s program logic.

%I Addresses

Bus B

(8193..16384)

%AI Addresses

Bus B

(8193..16384)

D

I_

O

F

S

T

A

I_

O

F

S

T

Figure 3: System and Dual Bus References

Each Genius device that has been configured to have discrete inputs must have one block of references

assigned to

Bus A

and a separate unique block of references assigned to

Bus B

. The application logic is

always solved using the references that are assigned to

Bus A

. There is fixed offset that specifies the location

of

Bus B

references relative to

Bus A

.

The references for analog inputs are configured in a similar fashion.

The offset for discrete inputs (

DI_OFST

) and the offset for analog inputs (

AI_OFST

), as shown above, are

recommended values. However, they may be configured independently for each dual bus pair.

3.3

Dual Bus Mapping Description

The dual-bus application evaluates the attachment state for each Genius device on both of the busses.

•

If the device is attached to

Bus A

, then the corresponding inputs appearing in the

A

references are

valid and no further action is needed.

•

If the Genius device is attached to

Bus B

, then the inputs appearing in the

B

reference area are

remapped (i.e., MOVed) into the

A

reference area.

•

If the Genius device is not attached to either

Bus A

or

Bus B

, then the inputs will “

Hold Last State

”

.

There are two choices for the time period that the inputs are frozen.

o

Normally, the inputs are frozen for a specified time. When the period expires, the values in

the block of references are reset to OFF or 0. The preset time may be configured

independently for each pair of dual busses.

o

Or, the alternate choice is to hold last state continuously until the device re-attaches to one

of the busses.

•

A fault message will be posted in the PLC Fault Table if a device changes its online/offline state for the

dual bus.