Performance Data Sheet

SmartWater

™

Filtration System―GE Appliances MWF Cartridge

The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible

limit for water leaving the system as specified in NSF/ANSI Standard 42 and Standard 53. System tested and certified by NSF International against

NSF/ANSI Standard 42 and Standard 53 for the reduction of substances listed below.

The following pharmaceutical reduction claims have not been certified by NSF International or the state of California.

Claims tested and verified by independent laboratory:

Contaminant

Reduction

Average Influent

NSF specified

Challenge Concentration

Avg %

Reduction

Average Product

Water

Concentration

Max Permissible

Product Water

Concentration

NSF Reduction

Requirements

NSF

Test Report

Atenolol

978 ng/L

N/A

99.5%

5.0 ng/L

N/A

N/A

J-00121587

Fluoxetine

907 ng/l

N/A

99.4%

5.4 ng/L

N/A

N/A

J-00121587

Ibuprofen

885 ng/L

N/A

94.1%

52.3 ng/L

N/A

N/A

J-00121588

Progesterone

1097 ng/L

N/A

99.5%

5.0 ng/L

N/A

N/A

J-00121589

Trimethoprim

415 ng/L

N/A

99.5%

2.0 ng/L

N/A

N/A

J-00121587

It is essential that the manufacturer’s recommended installation, maintenance and filter replacement requirements be carried out for the product to perform as advertised.

See Installation Manual for Warranty information.

Application Guidelines/Water Supply Parameters

Service Flow

0.5 gpm (21.9 lpm)

Water Supply

Potable Water

Water Pressure

40-120 psi (2.8-8.2 bar)

Water Temperature

33°F-100°F (0.6°C-38°C)

Note:

While the testing was performed under standard laboratory conditions,

actual performance may vary.

Replacement Cartridge: MWF. For estimated costs of replacement elements

please call 1-800-626-2002 or visit our website at www.geapplianceparts.com.

To reduce the risk associated with ingestion of contaminants:

•

Do not use with water that is microbiologically unsafe or of unknown quality

without adequate disinfection before and after the system.

Systems certified

for cyst reduction may be used on disinfected water that may contain filterable

cysts. EPA Establishment Number 10350-MN-005.

NOTICE

To reduce the risk associated with property damage due to water leakage:

•

Read and follow

use instructions before installation and use of this system.

• Installation and use

MUST

comply with all state and local plumbing codes.

•

Do not

install if water pressure exceeds 120 psi (8.2 bar). If your water pressure

exceeds 80 psi, you

must

install a pressure-limiting valve. Contact a plumbing

professional if you are uncertain how to check your water pressure.

•

Do not

install where water hammer conditions may occur. If water hammer

conditions exist you

must

install a water hammer arrester. Contact a plumbing

professional if you are uncertain how to check for this condition.

•

Do not

install on hot water supply lines. The maximum operating water

temperature of this filter system is 100º F (38º C).

•

Protect filter from freezing.

Drain filter when temperatures drop

below 33ºF (0.6ºC).

•

must

be replaced every

6

months at the

rated capacity, or sooner if a noticeable reduction in flow rate occurs.

For conditions of use, health claims certified by the California Department of Public

Health, and replacements, see performance data sheet. California Department

of Public Health Certification #05-1698. The contaminants or other substances

removed or reduced by this water filter are not necessarily in all users’ water.

Capacity 300 Gallons (1,135 Liters). Contaminant Reduction Determined by NSF testing.

Substance Tested

for Reduction

Average Influent

NSF specified

Challenge Concentration

Avg %

Reduction

Average Product

Water

Concentration

Max Permissible

Product Water

Concentration

NSF Reduction

Requirements

NSF

Test Report

Chlorine Taste and Odor

2.0 mg/L

2.0 mg/L ± 10%

97.5%

0.05 mg/L

N/A

≥ 50%

J-00077703

Nominal Particulate

Class I, , ≥0.5 to < 1.0 μm 7,833,333 pts/mL

At least 10,000 particles/mL

99.7%

18,617 pts/mL

N/A

≥85%

J-00077704

Cyst*

101,000 cysts/L

Minimum 50,000 cysts/L

99.99%

1 cyst/L

N/A

≥99.95%

J-00100036

Asbestos

47 MF/L

107 to 108 fibers/L; fibers

greater than 10 μm in length

>99%

<1 MF/L

N/A

≥99%

J-00077707

Atrazine

0.009 mg/L

0.009 mg/L ± 10%

94.5%

0.0005 mg/L

0.003 mg/L

N/A

J-00077708

Benzene

0.016 mg/L

0.015 mg/L ± 10%±

96.7%

0.0005 mg/L

0.005 mg/L

N/A

J-00077717

Carbofuran

0.08 mg/L

0.08 mg/L ± 10%

98.7%

0.001 mg/L

0.04 mg/L

N/A

J-00077718

Endrin

0.007 mg/L

0.006 mg/L ± 10%

97.1%

0.0002 mg/L

0.002 mg/L

N/A

J-00100039

Lead @ pH 6.5

0.152 mg/L

0.15 mg/L ± 10%

99.3%

0.001 mg/L

0.010 mg/L

N/A

J-00077722

Lead @ pH 8.5

0.148 mg/L

0.15 mg/L ± 10%

99.3%

0.001 mg/L

0.010 mg/L

N/A

J-00077723

Lindane

0.002 mg/L

0.002 mg/L ± 10%

99.0%

0.00002 mg/L

0.0002 mg/L

N/A

J-00077726

Mercury @ pH 6.5

0.0058 mg/L

0.006 mg/L ± 10%

93.2%

0.0004 mg/L

0.002 mg/L

N/A

J-00100037

Mercury @ pH 8.5

0.0061 mg/L

0.006 mg/L ± 10%

93.2%

0.0004 mg/L

0.002 mg/L

N/A

J-00092355

P-Dichlorobenzene

0.222 mg/L

0.225 mg/L ± 10%

99.8%

0.005 mg/L

0.075 mg/L

N/A

J-00077729

Tetrachloroethylene

0.015 mg/L

0.015 mg/L ± 10%

96.7%

0.0005 mg/L

0.005 mg/L

N/A

J-00082184

Toxaphene

0.015 mg/L

0.015 mg/L ± 10%

93.2%

0.001 mg/L

0.003 mg/L

N/A

J-00077730

2,4-D

0.218 mg/L

0.210 mg/L ± 10%

99.5%

0.0009 mg/L

0.07 mg/L

N/A

J-00085470

*Based on the use of Cryptosporidium parvum oocysts.

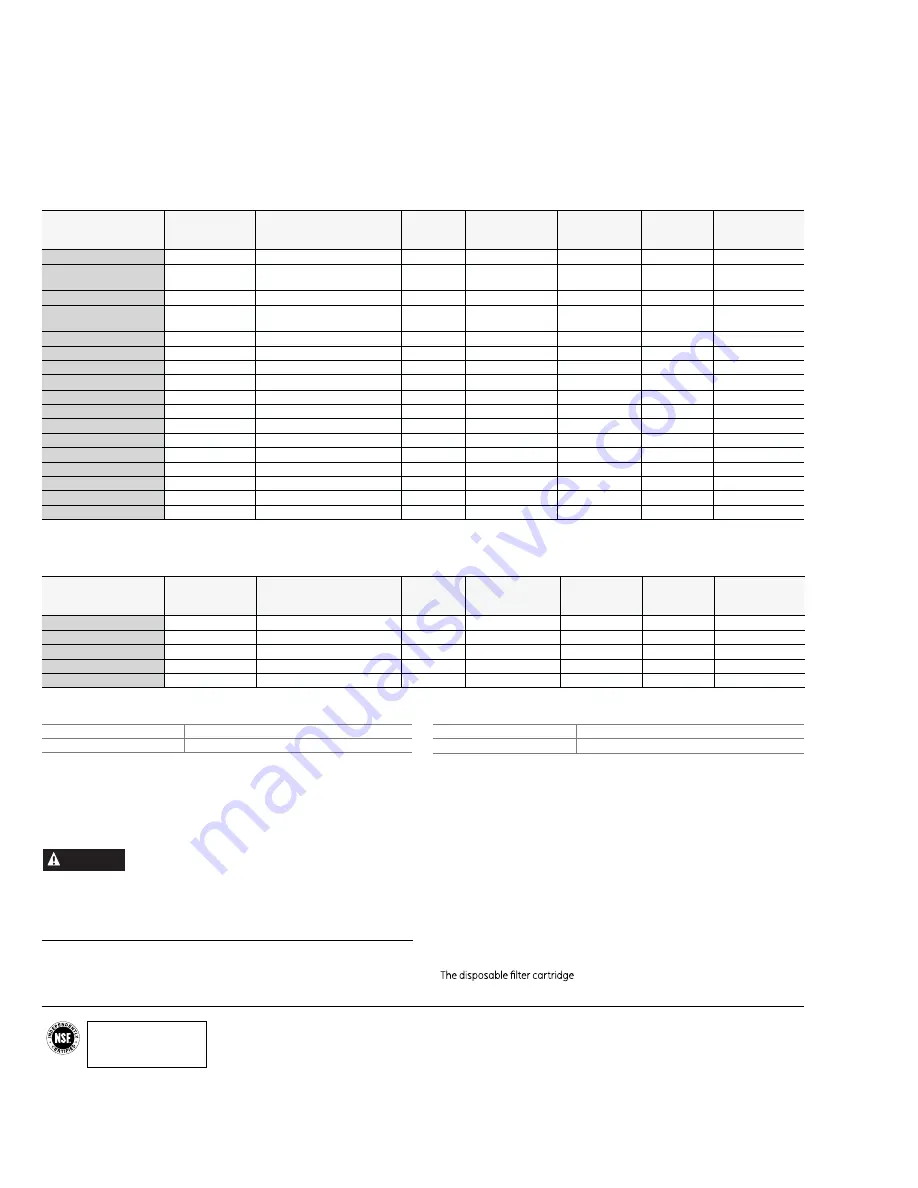

Tested and certified by NSF International

against NSF/ANSI Standard 42 and

Standard 53 in model GE Appliances MWF

for the reduction of the claims specified

on theperformance data sheet.

REPLACEMENT

ELEMENT

WARNING

42

Summary of Contents for Profile 24 CustomStyle

Page 43: ...43...