– 25 –

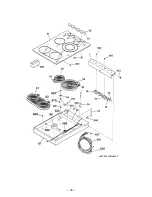

Surface Element Replacement

Note: The surface element, pan sensor, and

temperature sensor are

only replaceable as an

assembly, which includes the sensor wire harness

and connector.

1. Remove the glass and cooktop from the

countertop (see the procedure).

5. When the TIMER window displays

DISC and

the U symbol stops flashing in the LF surface

element power window,

center the aluminum

disk on the LF surface element.

6. Press the PAN and LF (+) keys at the same

time. The electronic control will perform the

calibration on the LF sensor and then proceed

to the next surface element. The TIMER

window will flash

CAL and the U symbol will

flash in the LR surface element power window.

7. Repeat steps 5 and 6 for the LR, CR (if

present), RR, and RF surface elements.

8. After the RF surface element has been cali-

brated, the timer window will display a PASS or

FAIL message for the entire calibration proce-

dure. An

F will be displayed in the surface

element power window of any sensor that fails

the process. Acknowledge this message and

exit the calibration procedure by pressing the

PAN and RF (+) keys at the same time.

Note: If the calibration proceedure is interupted for

any reason, exit the calibration proceedure by

pressing the PAN and RF (+) keys at the same

time.

Note: Failure of the calibration procedure may

occur for several reasons. If the calibration proce-

dure fails, follow these steps:

• Try calibrating the cooktop again, beginning with

step 1 from above.

• Identify the sensor(s) that fails the calibration

procedure.

• If multiple sensors fail the calibration procedure,

replace the logic board.

• If only one sensor fails the calibration procedure,

replace the corresponding surface element.

Caution: Do not cut the wire ties from the wire

harness. Care

must be taken to ensure that

only the sensor wires to the surface element

being replaced are cut.

Caution: Routing of the wires is extremely

critical. Care must be taken to ensure the wires

are routed exactly the way they were originally.

GEA00756

Sensor Wire

Harness

Surface Element

Power Wires

Remove Cut Wires

From Wire Bundle

Tie Wrap (Do Not Cut)

To Power Board

Old Heating

Element

3. Using diagonal cutters, snip

both the tempera-

ture sensor and the pan sensor wires and

remove them from the wire harness leading

from the logic board to the surface element.

Note: When installing the new surface element,

tie-wrap temperature sensor and pan sensor wires

to the existing wire harness. Do

not cut existing

wire harness. Do

not cut existing tie wraps.

GEA00861

Surface Element

Power Wires

Existing Wire Ties

(Do Not Cut)

To Power Board

New Heating

Element

Tie-Wrap New Wires

To Wire Bundle

2.

Disconnect the appropriate sensor connector

from the logic board by pulling

upward on the

connector. (Do

not disconnect the connector by

pulling on the sensor wires.) Trace the sensor

wires back to the appropriate surface element,

making note of where and how the wires are

routed.

Summary of Contents for Profile JP938

Page 19: ...17 Fault Code Behavior Table...

Page 33: ...31 Notes...

Page 34: ...32 Parts List...

Page 36: ...34...

Page 38: ......

Page 39: ......