– 73 –

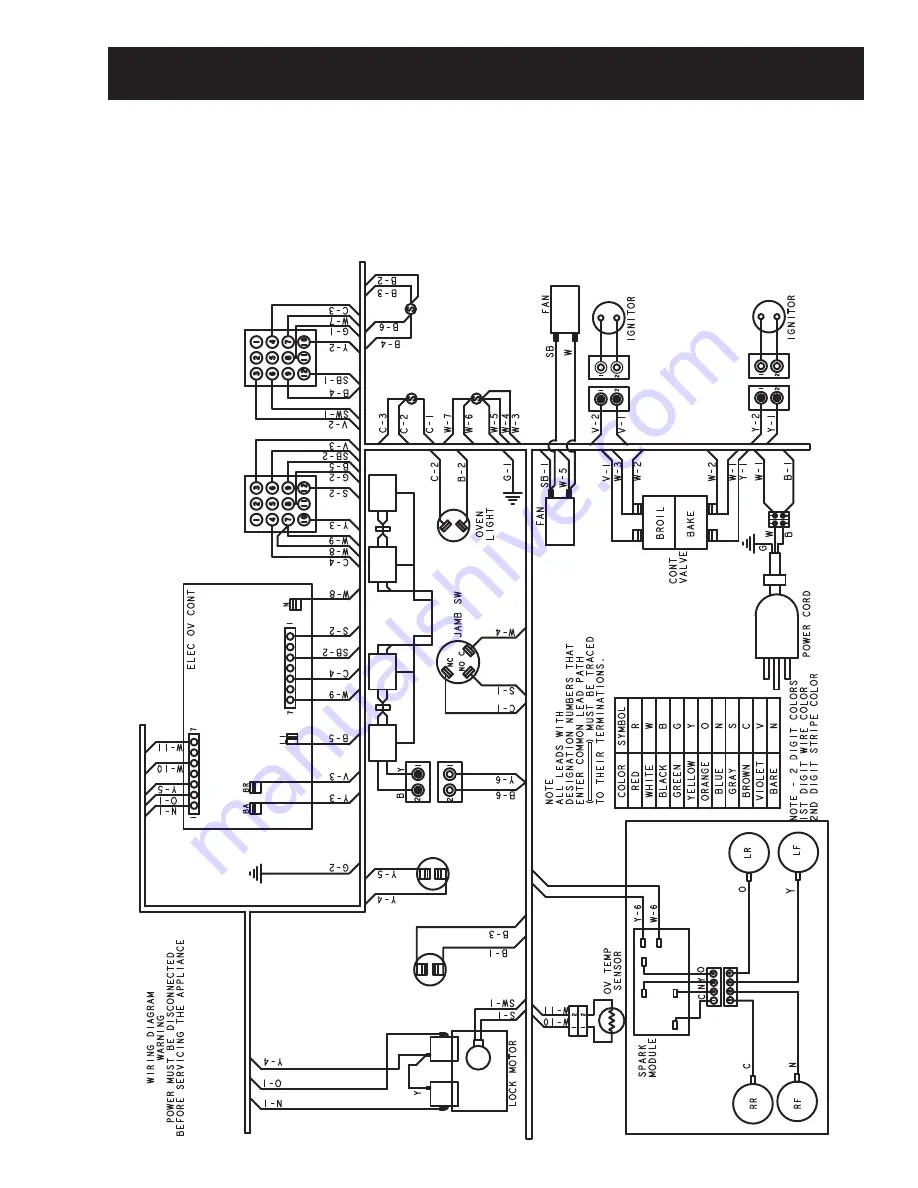

WARNING:

Disconnect electrical power before servicing.

Caution

: Label all wires prior to disconnection. Wiring errors can cause improper and dangerous operation.

Verify operation after servicing.

Schematics and Wiring Diagrams

(

Continued next page

)

THERMAL

SWITCH

THERMAL

LINE BREAK

PGS908 Wiring Diagram