– 27 –

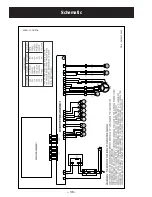

Hall Sensor

The Hall effect sensor measures the motor rpm.

•

Four wires connect the Hall sensor to the

•

inverter board at the 4-pin dark blue connector.

(See

Inverter and Main Board Pin Connectors.

)

The Hall sensor measures approximately 9K

•

Ω

between the brown and blue wires and the

brown and red wires.

If the sensor has failed, the motor will not

•

operate.

The Hall sensor is part of the stator assembly. It

•

is not available as a separate part.

To check the Hall sensor voltage at the inverter:

Disconnect the Hall sensor plug from the

•

inverter board. Check voltage on pins 3 (brown)

and 4 (yellow) on the inverter board. There

should be approximately 12 VDC. If not, the

inverter board is bad.

To check voltage at the Hall sensor:

Measure between pins 1 (blue) and 4 (yellow)

•

and pins 2 (red) and 4 (yellow) with the Hall

sensor plugged into the inverter board. Rotate

the spin basket by hand. There should be 12-

VDC pulses as the basket is rotated. If the pulses

are present, the Hall sensor is good.

1

2

3

4

Inverter Board

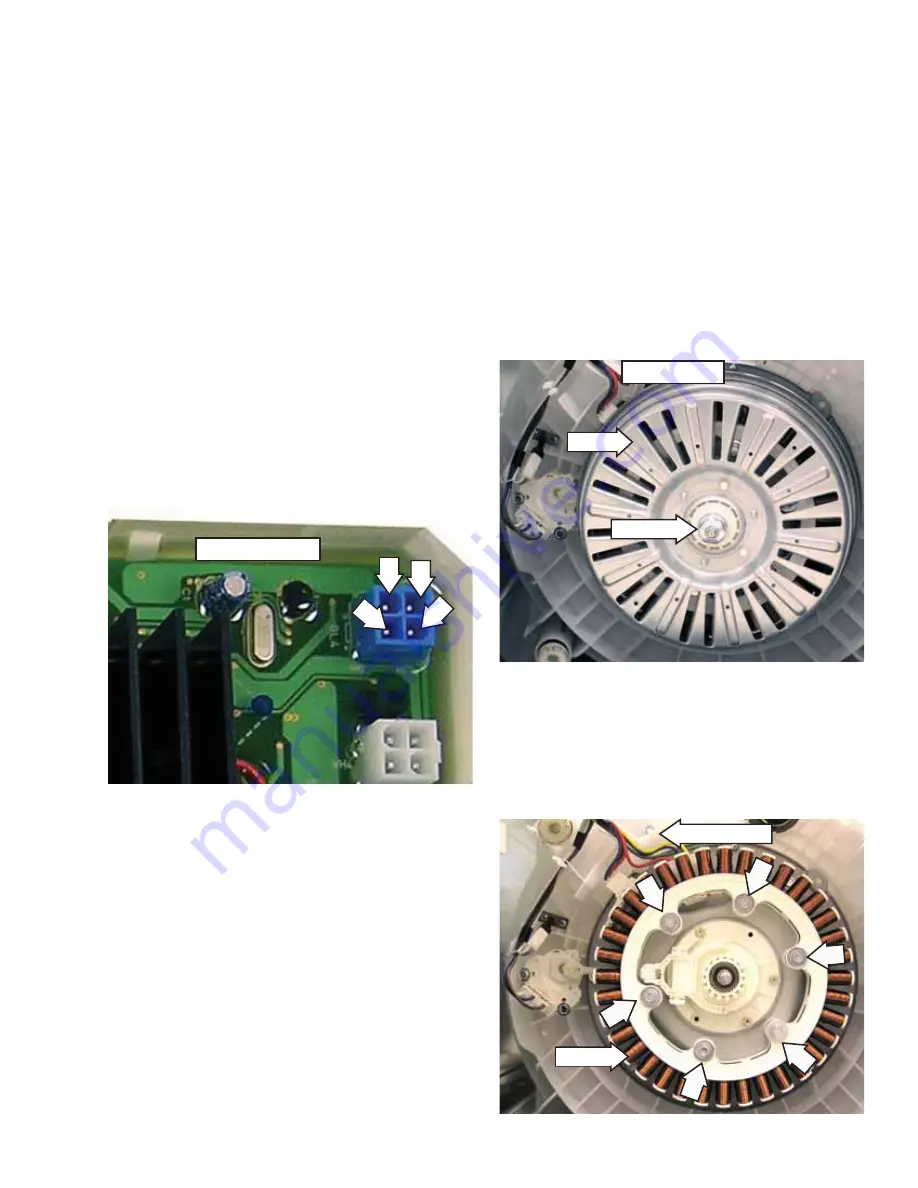

To remove the rotor and stator:

WARNING: The rotor is not grounded. Unplug the

washer before servicing to avoid electrical shock.

To access the motor, the washer must be placed

1.

on its side. Place a towel or blanket on the

fl oor to prevent scratches to the surface of the

washer.

Remove the 24-mm (

2.

15

/

16

in. SAE equivalent)

rotor nut with a socket or adjustable Crescent

wrench (rotate rotor nut counterclockwise to

remove).

Note

:

Use a rubber mallet if needed to tap the

wrench to break the nut free.

3. Pull the rotor away from the drive shaft.

4. Remove the six 10-mm hex-head screws that

hold the stator in place.

Note

:

Removal of the wiring guard (held in place by

one 10-mm hex-head screw) will give better access

to the motor connector.

Bottom View

Rotor

Rotor Nut

Wiring Guard

(Continued Next Page)

Stator

Summary of Contents for Profile WPGT9150

Page 37: ... 37 ...