– 25 –

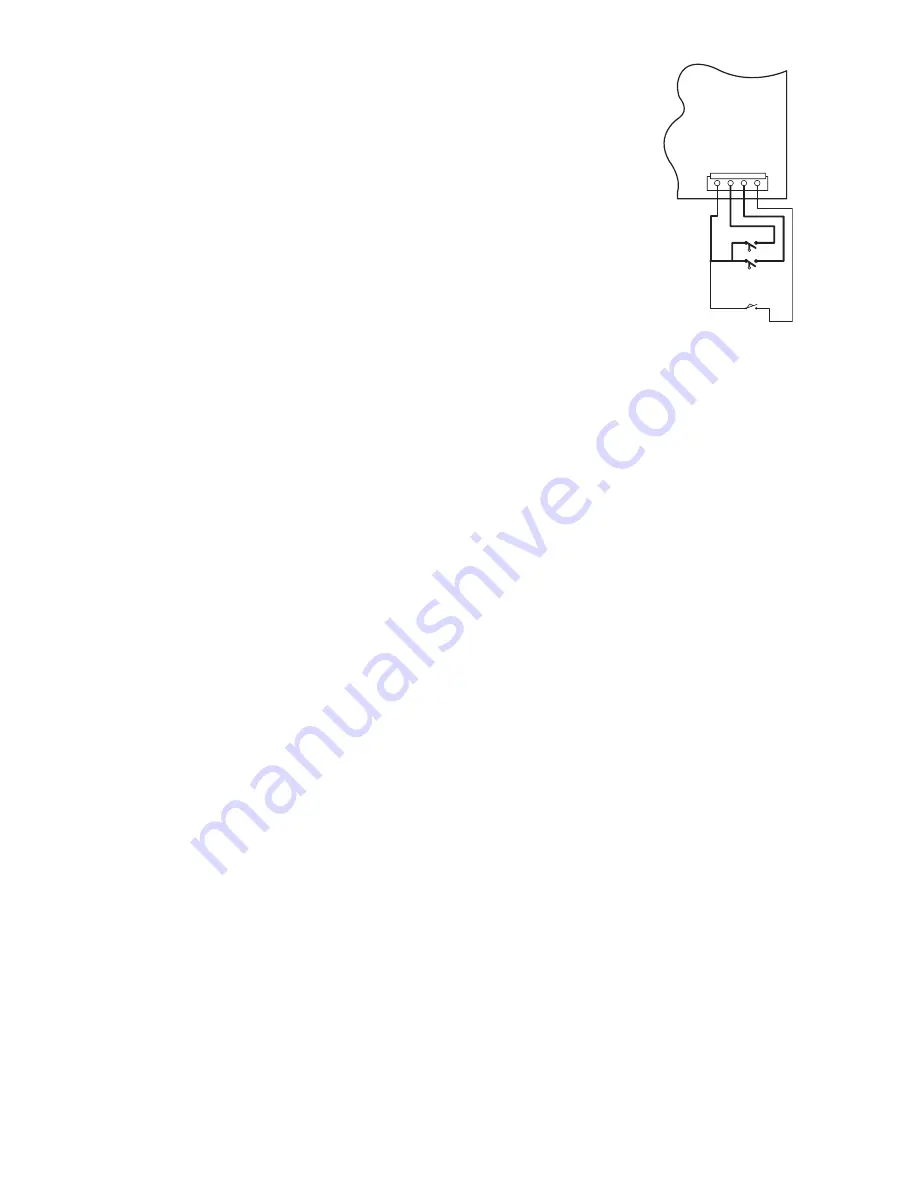

Water Level Switch

Note: Also refer to Water Level (Load Size) Diagnostic.

The water level switch has two switches in one housing and is

located inside the control panel. The water level switch is

connected by a hose to an air reservoir near the bottom of the outer

tub. When the water level rises in the washer tub, air is trapped in

the reservoir. As the water level rises, the air pressure in the

reservoir increases. When 6 inches of water have accumulated in

the washer tub, the appropriate pressure will be achieved and the

low switch will open. The high switch will open when the water in

the tub has reached its maximum level. Mid-level fills are timed,

based on the amount of time it took to fill to lowest level.

This Profile model is equipped with a flood protection feature. If the low level pressure switch is

opened while the washer is in idle mode, the electronic control will activate the drain pump to extract

any water in the tub. The rate of water extraction during flood protection exceeds the rate of fill under

normal conditions. The pump will continue to operate for 60 seconds after the low level switch has

closed.

Water Level (Load Size) Diagnostics

To determine if the water level switch and electronic control board are functioning correctly, perform the

following:

1. Place the unit in service mode.

2. Index to the Low Level Pressure Switch test and press start. The washer will fill with water until the

low level pressure switch opens at the extra low level, approximately 6.1 inches.

3. Index to the High Level Pressure Switch test and press start. The washer will fill with water until the

high level pressure switch opens at the giant level, approximately 14 inches.

Note: It will be necessary to shut the lid in order to reset the electronic control board and advance to

the next water level.

Each load size should be at the following level:

•

Giant - 14.0 (+/- 0.5) inches, 26.3 gallons

•

Large - 12.5 (+/- 0.5) inches , 23.1 gallons

•

Medium - 10.4 (+/- 0.5) inches, 19.9 gallons

•

Small - 8.2 (+/- 0.5) inches, 16.8 gallons

•

Extra Small - 6.1 (+/- 0.5) inches, 13.6 gallons

If the water level of an Extra Small Load is deeper than 6.1 (+/- 0.5) inches, check to see that the water

level switch is closed when the water level is below 6.1 (+/- 0.5) inches and that it is open when the water

level is 6.1 (+/- 0.5) inches and above. If the water level sensor functions properly, replace the electronic

control board.

Note: Small, Medium, and Large Load Size water levels are timed in the electronic control board. The

timing is based on the amount of time it takes to fill to the lowest level.

If the water level of a Small, Medium, or Large Load is deeper than 8.2 (+/- 0.5) inches (Small), 10.4

(+/- 0.5) inches (Medium), or 12.5 inches (Large), check to see that the Extra Small Load water level is

operating normally (see above paragraph). If the Extra Small Load operates normally, replace the

electronic control board.

If the water level of a Giant Load is deeper than 14.0 (+/- 0.5) inches, check to see that the water level

switch is closed when the water level is below 14.0 (+/- 0.5) inches, and that it is open when the water level

is 14.0 inches and above. If the water level sensor is functioning properly, replace the electronic control

4

J10

J8

+12V

PRESSURE SWITCH HIGH

PRESSURE SWITCH LO

W

COM

11

HI

16

LOW

12

WATER

LEVEL

SWITCH

3 2 1

Summary of Contents for Profile WPRB9220

Page 6: ... 4 Control Features WPRB9250 WPRB9220 ...

Page 35: ... 33 Notes ...