Page 51

XI. SPECIAL EDITION ON MAINTENANCE OF ENVIRONMENTAL PROTECTION

REFRIGERATOR

l.

Vacuum extraction for 20

minutes till the valve becomes

the condition of Fig. (11).

m. After the vacuum extraction,

close all the valves.

n.

Identify the graduation of the

filling tube.

o.

Open LB valve and seal the

required amount of freon

through BC valve.

Seal the required amount of freon through CB valve and

then adjust by the graduation of the filling tube.

p.

The condition of valve after

sealing the freon (only LB valve

is left open).

LB

VB

HB

L

H

CB

Vacuum pump stops

L

H

CB

LB

VB

LB

L

H

q.

The high pressure gauge

should be over 1.0 kgf/cm

2

G

and then use the sealing

wrench to seal the filling tube

from this end. Then remove

the compound pressure gauge

and seal the front end of the

filling tube.

When sealing the filling

tube at pressure below 1.0

kgf/cm

2

G, the air may be

sucked in.

r.

Run the refrigerator

compressor and push the

freon of the filling tube and

compound pressure gauge

into the system.

When the low pressure

gauge is pointing at 1.0

kgf/cm

2

G, close LB valve to

stop the compressor.

L

H

L

H

LB

Summary of Contents for PTV15SAMR

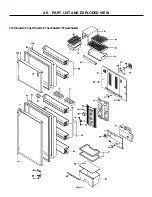

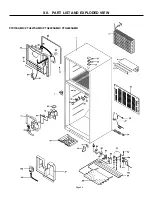

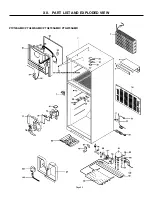

Page 53: ...Page53 XII PART LIST AND EXPLODED VIEW PTV15SAMR PTU427SAMR PTQ440SAMR PTG440SAMR...

Page 54: ...Page54 XII PART LIST AND EXPLODED VIEW PTV15SAMR PTU427SAMR PTQ440SAMR PTG440SAMR...

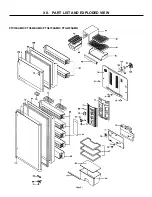

Page 61: ...Page61 XII PART LIST AND EXPLODED VIEW PTV16SAMR PTU463SAMR PTQ470SAMR PTG470SAMR...

Page 62: ...Page62 XII PART LIST AND EXPLODED VIEW PTV16SAMR PTU463SAMR PTQ470SAMR PTG470SAMR...

Page 70: ...Page70 XII PART LIST AND EXPLODED VIEW PTV19SAMR PTU527SAMR PTQ530SAMR PTG530SAMR...

Page 71: ...Page71 XII PART LIST AND EXPLODED VIEW PTV19SAMR PTU527SAMR PTQ530SAMR PTG530SAMR...

Page 78: ...Page78 XII PART LIST AND EXPLODED VIEW PTV20SAMR PTU565SAMR PTQ570SAMR PTG570SANR...

Page 79: ...Page79 XII PART LIST AND EXPLODED VIEW PTV20SAMR PTU565SAMR PTQ570SAMR PTG570SANR...