SecoGear 24kV-27kV Air Insulation Switchgear

32

Spare parts

Please refer to recommended spare parts list below. Other spare parts are also available based on customer's requirement.

S/N

Name

Unit

Comments

1

Heater

Piece

2

Key for door lock

Piece

3

Earthing switch operating handle

Piece

4

27KV Service Truck T800

Set

5

27KV Service Truck T1000

Set

Appendix A - Onsite service safety instruction

Before operating the equipment, please check and make sure to

follow all safety requirement.

If for any reason the work is interrupted, please make sure site

safety procedure is followed when restarting the work.

•

Before operating, please check site layout, both inside

and outside of the electrical operating area, earthing line

layout, ON or OFF condition of the control power, state of

the temporary power, and if any personnel is present and all

safety/emergency exits are clear.

•

Ensure if safety procedures on working sheet are well

implemented, recheck if the safety procedures comply with

requirements, if isolation procedure between live equipment

and test equipment is established, and there are clear

instructions on the product labels.

The connection sequence as follows:

Confirm the equipment be powered off and make sure to

follow proper safety measures.

•

One side of conductor is connected with wall bushing

by using one screw(M5X8) and a flat washer, required

torque is 5Nm.

•

Another side of connecting conductor is connected

with main busbar by using another screw(M5X10) and

a flat washer, required torque is 5Nm.

•

Replacement can be done with the above instructions

following the previous instructions in reverse order.

•

Once equipment is in power off phase, it is strictly forbidden

to operate the circuit breaker or switch. Please switch OFF

circuit breaker and move VCB to test or withdrawn position.

Instrument and power transformer to power of the equipment

shall be switched off in order to avoid any unintended

charging of the equipment.

•

Please confirm the switchgear reference data and series

number to avoid working on the wrong equipment.

•

All current transformer and voltage transformer secondary

winding shall only have one permanent and reliable protective

earthing.

•

If it is necessary that personnel must service the switchgear,

please make sure to contact GE or that site personnel is

properly trained and are capable of following proper safety

measures.

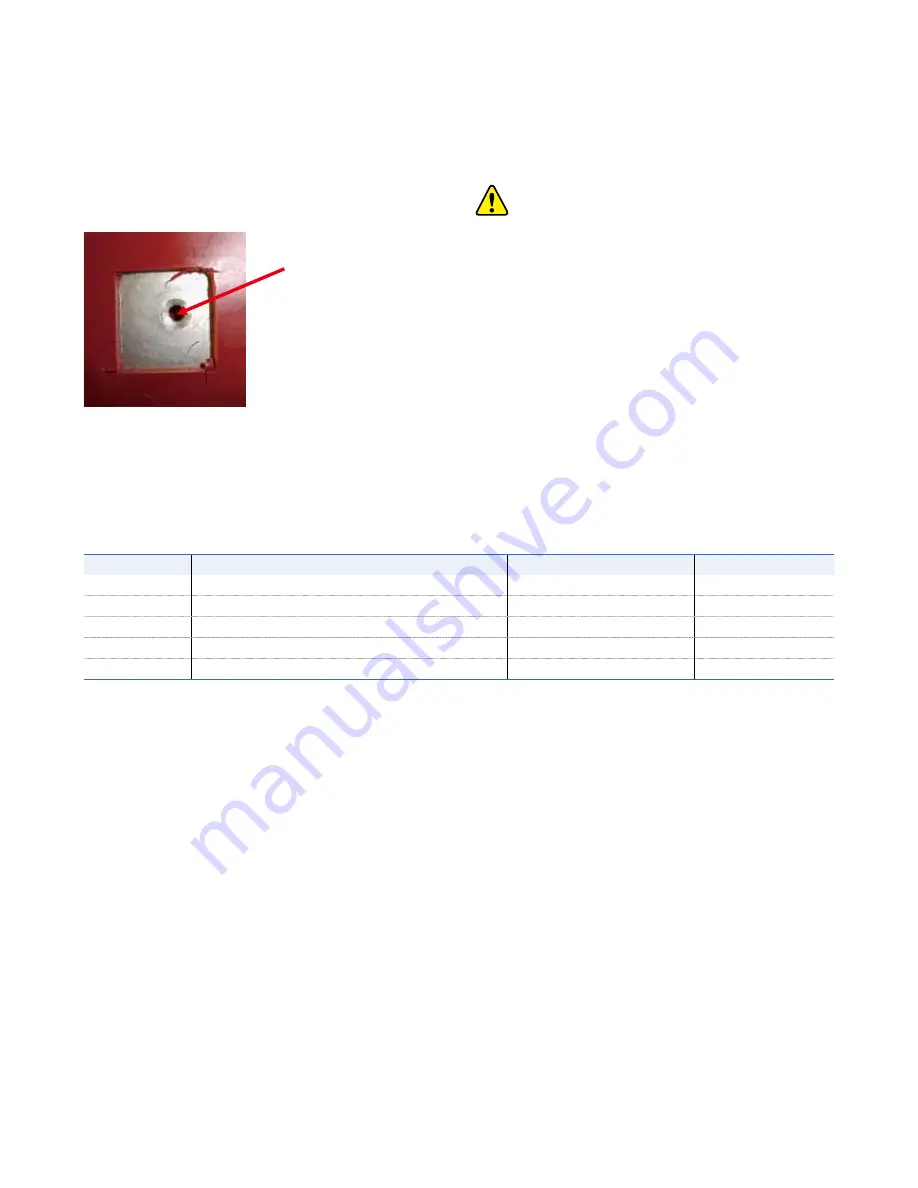

Cut off the heat-shrinkable tube (the surface side which close

the conductor) with the area of 30x30mm around the threaded

hole (See Figure 6/16).

Figure 6/17

Threaded Hole (M5)