3.8 WIRING CONNECTION

WARNING!

UPS installation and connection must be performed by QUALIFIED SERVICE

PERSONNEL ONLY.

3.8.1 Power connections

Input/output and DC connections are provided with terminal blocks.

Please refer to chart for torque specifications.

Carefully read the following recommendations before proceeding:

•

Ensure that the AC and DC external isolators are OFF and locked to prevent their inadvertent

operation.

•

Do not close any external isolators prior the commissioning of the equipment.

•

The preferred power cable entry location for installation purposes is from the right side of the UPS,

either top or bottom.

In case of cable entry from the top of the cabinet, remove the cover plate fitted on the roof and

provide for a suitable isolated protection cover.

In case of cable entry from the bottom remove cover plate and perform the same procedure.

•

If the UPS is installed in such a way that the accessibility to the right side panel is reduced, field

wiring connections can be made from the front side by removing the front right side panel

protection cover/panel ( E ) as indicated in

Fig. 3.8.1-1

be advised that installation performed from

the front position will give the installer reduced visibility to the terminal lugs.

•

The input/output cables must be connected in clockwise phase rotation for both

Bypass

and

Rectifier Input Terminals

if separate, taking care to avoid risk of short circuit between different poles.

•

The grounding and neutral connection of the electrical system must be in accordance with local

regulations.

•

In case of additional cabinets containing batteries, input/ output transformers, etc, their ground

terminals must be connected to the UPS main ground terminal.

•

Once the power cables have been connected, re-install the internal safety shields and close the

cabinets by re-installing all external panels.

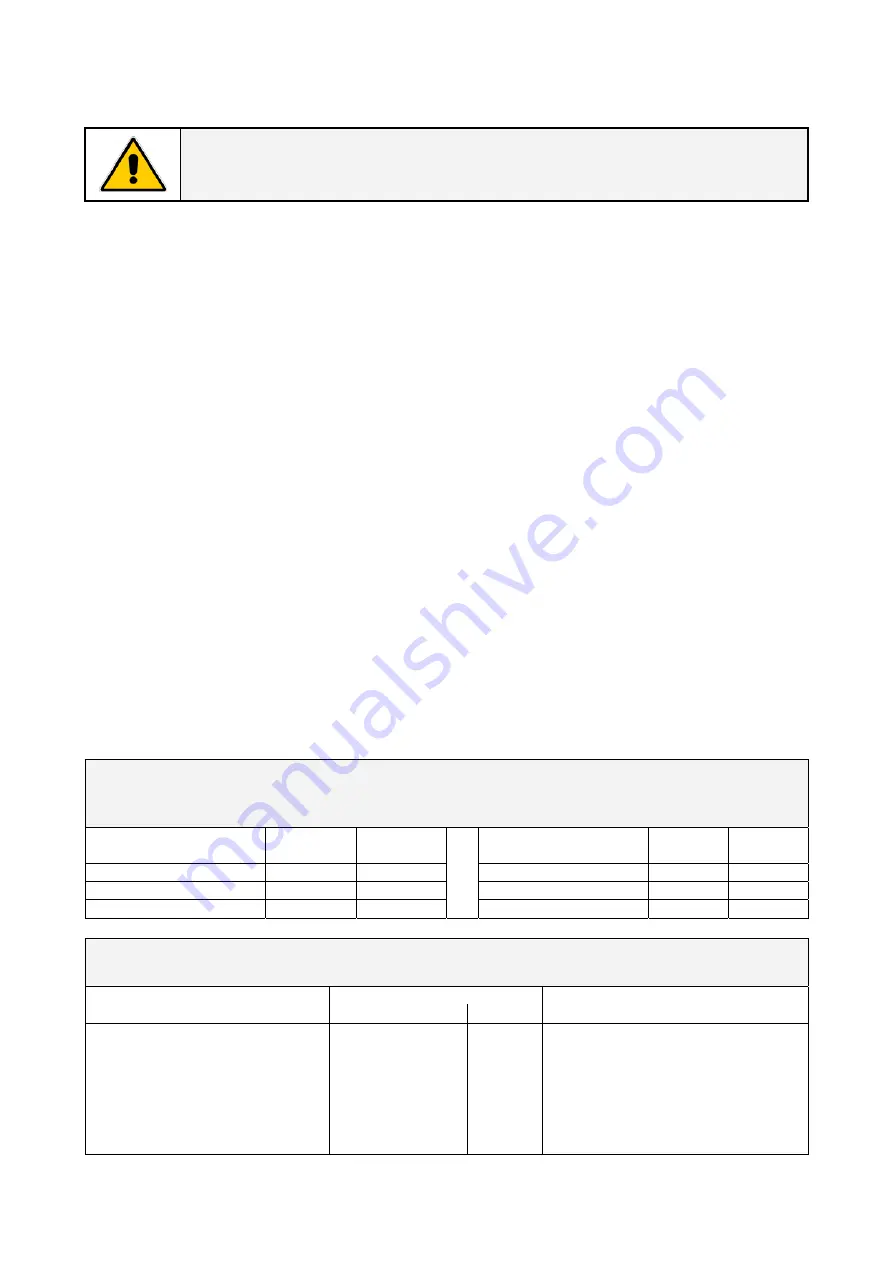

Torque Specifications

Mechanical Compression Lugs

Input / Output / Battery

WIRE SIZE RANGE

AWG / kcmil

Lb - in

Nm

WIRE SIZE RANGE

AWG / kcmil

Lb - in

Nm

6 – 4

110 12.4

3/0 – 200

250 28.2

3 – 1

150 19.6

250 – 350

325 36.7

1/0 – 2/0

180 20.3

500 – 750

375 42.4

TERMINAL LUGS FOR FIELD WIRING CONNECTIONS

Provided for Terminal connections

CONNECTION TYPE

RATING

(A) GROUNDING

Allowed cable sizes

Torque

COMPONENT

3 lugs in total are used for each unit

•

One is used for

Input Grounding

•

One is used for

Output Grounding

•

One is used for

Battery Cabinet

Grounding

Terminals Lugs are secured to

chassis by means of two bolts.

1 x 350 MCM

325 Lb–in

Use only UL LISTED components.

Use two holed lug component.

See

Fig. 3.8.2-1

,

Fig.

3.8.3-1 &

Fig.

3.8.4-1

Modifications reserved

Page 21/40

OPM_SGS_ISG_M22_M30_2US_V010.doc

Installation Guide

SG Series 225 & 300 UL S2