Modifications reserved

Page 18/49

OPM_SGS_ISG_M75_M75_2US_V010.doc

Installation Guide

SG Series 750 UL S2

&

SG Series 750 T12 UL S2

3.5

VENTILATION AND COOLING

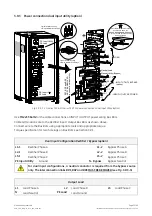

Fig. 3.5-1 Installation on solid floor

The heat produced by the UPS is transferred

to the environment by its ventilation.

Air inlets for UPS ventilation are located on the

front and bottom of the UPS, while air outlets

are on top of the cabinet.

A suitable ventilation or cooling system must

be installed to extract the heat from the UPS

room.

NOTE !

Do not put anything on the top of the cabinet.

Air filtration systems could be required when the UPS operates in a dirty environment.

Contact your

Dealer

or the nearest

Service Center

for appropriate solutions.

In order to prevent overheating of the UPS, the available air intake flow rate must exceed the total air

exhaust flow rate requirement of the UPS system.

The below tables indicate the heat dissipation at full

Load

at

PF = 0.9

lag. and charged

Battery

, up to

3,280 ft

(1,000 m) altitude, for cooling air

77°F

(25°C) to

86°F (

30°C).

Losses

Cooling air flow

UPS rating with options

BTU / hr

kW

CFM

m

3

/ h

SG Series 750 (6 pulse) with 5

th

filter

152,219 44.6 7,657 13,009

SG Series 750 (6 pulse) with 5

th

& 11

th

filter

154,949 45.4 7,794 13,242

SG Series 750 T12 (12 pulse) without filter

178,840 52.4 8,996 15,284

SG Series 750 T12 (12 pulse) with 11

th

filter

181,570 53.2 9,157 15,517

SG Series 750 (6 pulse) in eBoost™ Operation Mode

30,376 8.9 1,528 2,596

SG Series 750 T12 UPS in eBoost™ Operation Mode

32,765 9.6 1,649 2,800