4.1.3 Programmable input free contacts

Some programmable UPS functions (indicated in

Section 8.1

), can be activated by closing an external contact, if

connected, on:

X1 / 10, 21

or

J2 / 10, 23

User Input 1 (default = Not used)

X1 / 11, 22

or

J2 / 11, 24

User Input 2 (default = Emergency GEN ON)

4.1.4 Gen Set Signaling (GEN ON)

If an emergency generator set supplies the UPS in case of

Mains Failure

and the generator is considerably

unstable in frequency, it should be suitable to install the signal

“

Generator ON

”

on

X1 / 11, 22

or

J2 / 11, 24

). See

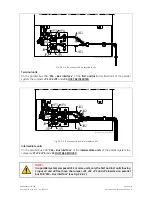

Fig. 4.1-1 / X1

and

J2.

Since the Parameter for of the reading of the Generator function is password protected, call the nearest

Service

Center

for it's activation.

When this contact closes, it changes certain (programmable) functions such as:

•

Enabling or disabling of synchronization and consequently the

Load

transfer to generator.

•

Reduction or elimination or delay of

Battery

recharging during the generator operation.

Additionally, when the

“

Generator ON

”

input contact is closed, the UPS will inhibit

eBoost™ Operation Mode

and

revert to double-conversion operation.

In a parallel system a separate NO (Normally Open) contact must be connected to each

individual unit.

4.1.5 AUX external Maintenance Bypass

If the UPS system is equipped with an external

Maintenance Bypass Switch

, it is possible to connect a

NO

(Normally

Open) voltage-free aux. contact from the

External Bypass Switch

to the programmable input

X1 / 10, 21

or

J2 / 10,

23

, making the UPS operate as if the internal switch

Q2

has closed.

This function can be activated by changing a dedicated parameter (password required).

When this

NO

(Normally Open) contact closes, the output

Inverter Contactor

K7

it is automatically opened and the

Load

transfer back to

Inverter

will be inhibited.

In a parallel system, the input on the customer interface of each unit must be connected to

a separate AUX contact of the External Maintenance Bypass Switch.

4.1.6 eBoost/IEMi control signal

The UPS operation in either

eBoost

or

IEMi

operating modes can be controlled via an

NO (Normally Open)

contact by

installing the “

eBoost/IEMi control

” signal, routed to the programmable function contacts (see

Fig. 4.1-1 / X1

and

J2

).

The Parameter for the activation of such function is password protected. Call the nearest

Service Center

for its

activation.

When this contact closes,

eBoost

or

IEMi

operation is inhibited.

This function is particularly useful for controlling

eBoost

or

IEMi

operation following critical conditions on either the

load side or the input utility, including generator operation when the “

Generator ON

” signal has not been installed.

When using the “eBoost/IEMi control” function on the programmable user relays of the

customer interface X1/J2 terminals in a parallel system, a separate NO (Normally Open)

contact must be connected to each individual unit.

4.1.7 Auxiliary Power Supply (APS) 24Vdc and Battery Breaker Release

S

G

S

_40

0-5

0

0_

U

P

S

_X

A

-X

B

_01

1

XA

2

3

4

4

2

3

1

XB

Terminals XA

1

2

3

4

SGS_400

-500_Ter

minals XA

_01

XA-1

24Vdc

XA-2

GND

XA-3

Positive

(+)

Battery Breaker Release Voltage

XA-4

Negative

(-)

Battery Breaker Release Voltage

Fig. 4.1.7-1 Terminals XA for connection 24Vdc and Battery Breaker Release

Modifications reserved

Page 39/41

OPM_SGS_ISG_M40_M50_2US_V021.doc

User Manual

SG Series 400 & 500 UL S2