IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, &

mechanical experience. Any attempt to repair a major appliance may

result in personal injury & property damage. The manufacturer or seller

cannot be responsible for the interpretation of this information, nor can it

assume any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this product.

If electrical power is required for diagnosis or test purposes, disconnect

the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position & properly fastened.

Summary of Contents for Spacemaker GTUP240EMWW

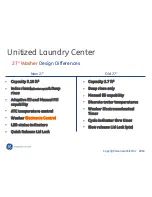

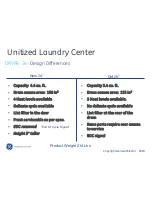

Page 1: ...24 27 Unitized Laundry Centers GTUP270EMWW GTUP270GMWW GTUP240EMWW GTUP240GMWW ...

Page 98: ...Copyright General Electric 2010 Washer Schematic ...

Page 99: ...Copyright General Electric 2010 Electric Dryer Schematic ...

Page 100: ...Copyright General Electric 2010 Gas Dryer Schematic ...

Page 101: ...Copyright General Electric 2010 ...