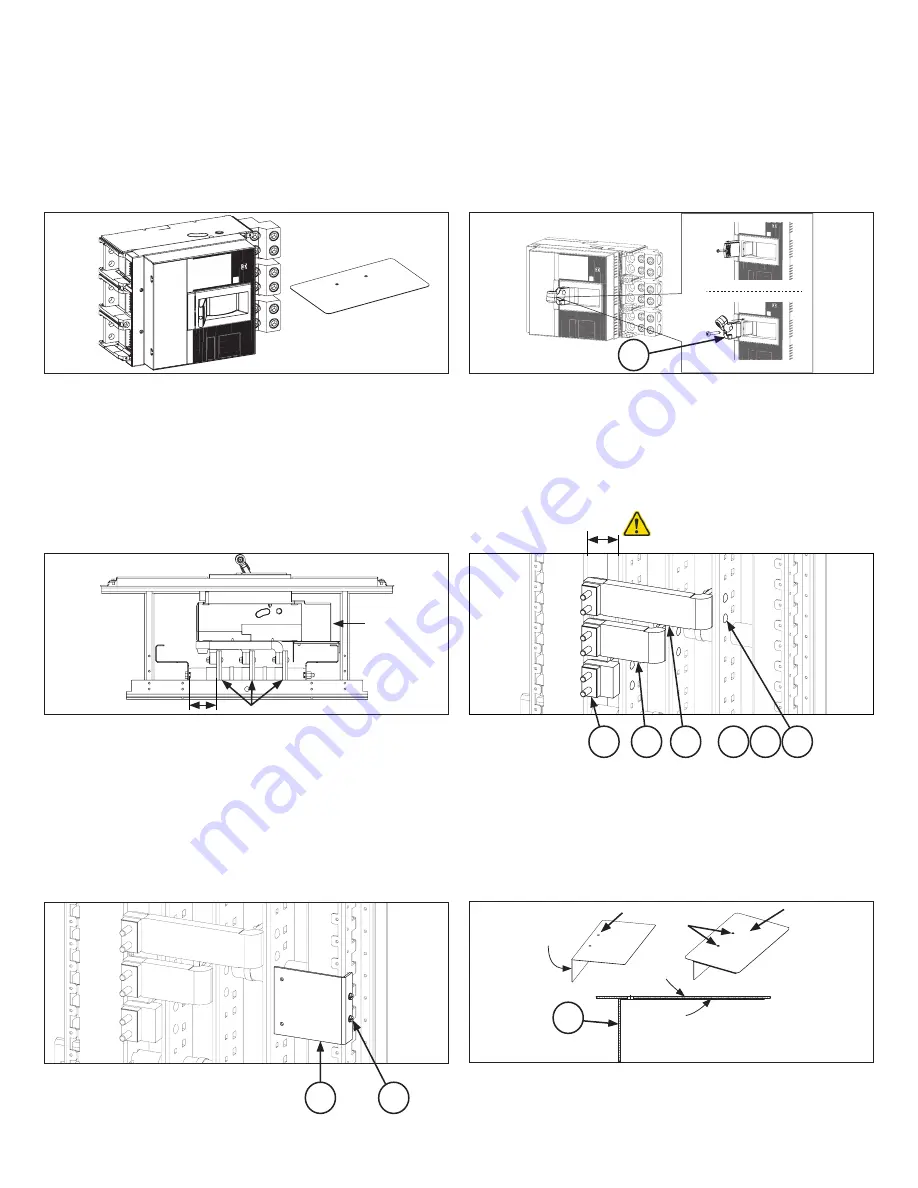

STEP 2

Remove flat cap and install foldable handle assembly (13) and

tighten the screw.

—

Figure 2. Install foldable handle assembly

STEP 4

Install the strap assemblies [10,11,12] with the corresponding

holes in the vertical bus, as shown in Figure 4. Fasten each strap

assembly loosely to the vertical bus with two carriage bolts [1],

Belleville washers [2] and nuts [3].

Main Bus

10

3

11

12

13

2

1

6x 6x 6x

2.75"

REF

LINE

LOAD

Cable entry

2.75" REF

Remove flat cap and screw

Install foldable handle assy

Figure 2a. Remove flat cap and screw

Figure 2b. Install foldable handle assembly

—

Figure 6. Prepare L-shaped barrier assembly

—

Figure 5. Installation of mounting bracket

STEP 5

Install the breaker mounting bracket [4] to the panel side rail with

thread forming screws [5], torque the screws to 35 lb- in. Refer

figure 5.

STEP 6

Prepare L-shaped barrier assembly. Fold L shaped barrier (8) as

shown in figure 6 and fix the breaker isolation base plate (sup

-

plied with breaker kit) to the adhesive surface of L shape barrier

(8) as shown in figure 6.

4

8

5

Folded

Breaker side

Adhesive side

Align holes

Breaker isolation

backplate

To mate with

mounting plate

2

STEP 1

Prepare the breaker, install required lugs and identify the re-

quired mounting and termination accessories from circuit

breaker kit. Refer to breaker instruction document for more infor-

mation.

—

Figure 1. Prepare the breaker

STEP 3

Find the side of the panel interior at which the dimension from

the face of nearest vertical bus to the inner face of the bus sup-

port rail is 2.75 inches, as illustrated in Figure 3.

—

Figure 3. Single branch, ABB XT7; Right side cable entry Assembly end view

—

Figure 4. Installation of link assy. A, B & C phase

2x