—

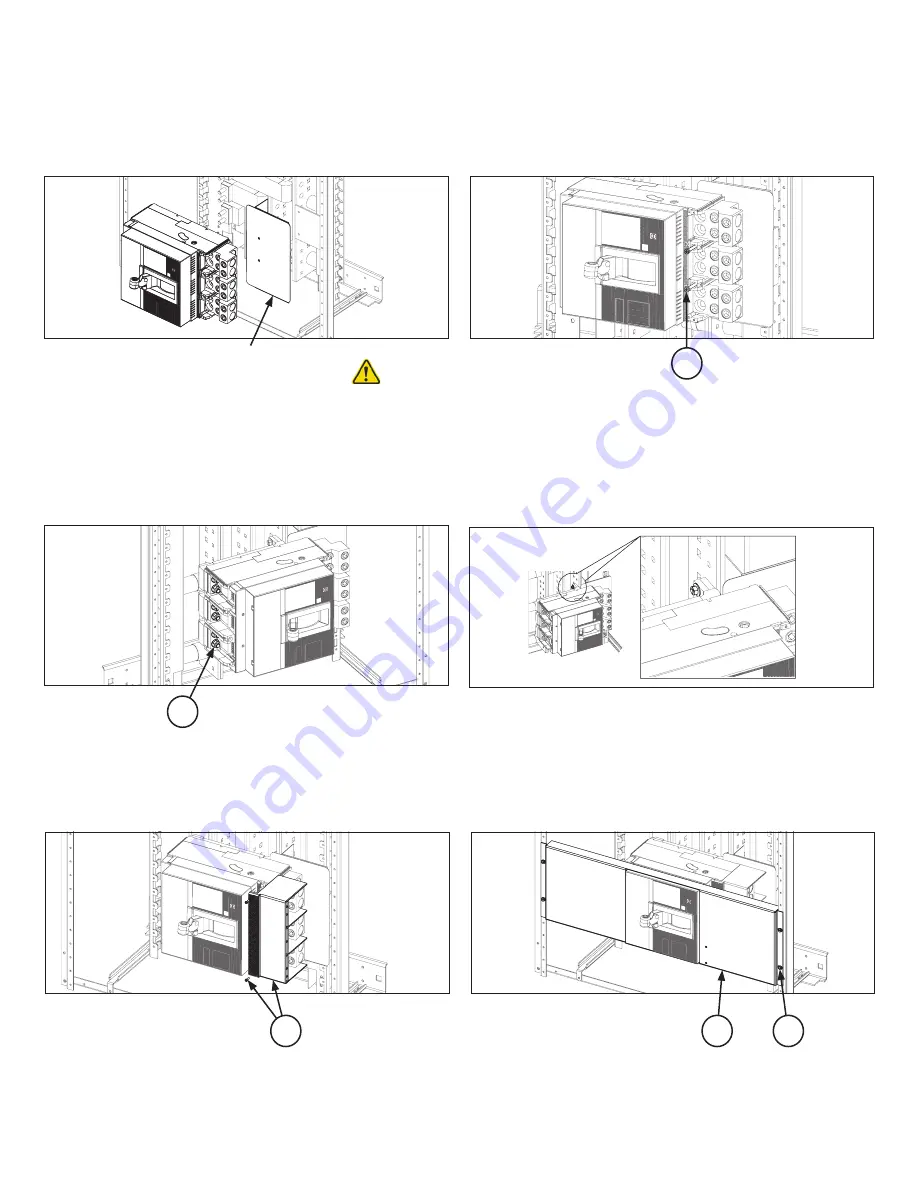

Figure 8. Tighten the bolted strap connections

—

Figure 7c. Flange nut

STEP 7 Continued

STEP 8

Tighten all the three bolted strap connections (carriage bolt as

-

sembly) at the vertical bus to 65 lb-in. It may be necessary to re-

move adjacent circuit breaker modules to allow access to the

bolted connections at the vertical bus.

6x

1x Terminal cover

2x Screws

4x

3

STEP 7 Continued

—

Figure 7b. Socket head screw

STEP 7

Install breaker with L-shaped barrier assembly [from STEP 6].

Refer figure 7a. Tighten Socket head screw [7] and flange nut [6],

torque the screw [7] to 22 lb-in. Torque the flange Nut [6] to 160

lb-in. Refer figure 7b and 7c.

—

Figure 7a. Installation of breaker and L shaped barrier assembly

7

2x

L-shaped barrier with

isolation base plate

[From STEP 6]

6

STEP 10

Install the filler plate [9] to panel with thread forming screw [5],

torque the screw to 35 lb-in. Refer figure 10.

—

Figure 10. Install filler plate

STEP 9

Install terminal cover (14) in the load side and secure with 2x sup

-

plied screws as shown in figure 9.

—

Figure 9. Install terminal cover

14

9

5