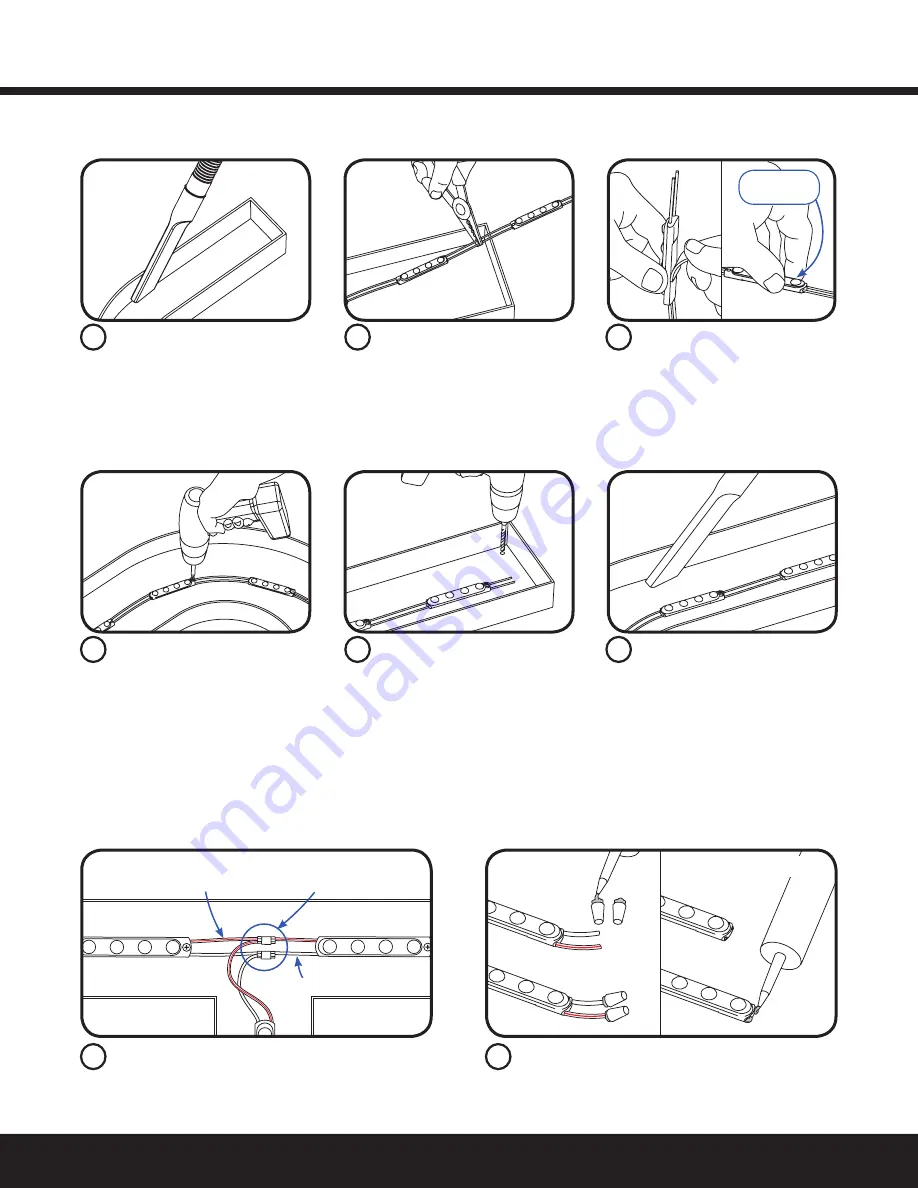

Measure and cut Tetra LED strip

to the appropriate length for

each letter. Cuts can be made

between any of the modules.

Use rivets, screws, or electrical

grade RTV silicone to secure

at least every fifth LED module

within the channel letter. Use #6

(M3) pan headed metal screws,

1/8-inch (3.2 mm) rivets, or

electrical grade RTV silicone.

Before you begin, clean surfaces

and remove all debris from the

inside of the channel letter.Clean

the surfaces with a 50:50 mixture

of isopropyl alcohol (IPA) and

water and let dry.

Layout Modules

Drill a 1/4-inch (6.4 mm) hole

near the LED strip and grommet

the hole for supply wire access.

Remove all the debris from the

inside of the channel letter and

replace the sign face.

NOTE: For halo-lit applications LED modules should be mounted on UL

recognized clear acrylic or polycarbonate. The light output from the LED

system should be directed back into the sign enclosure. This will allow for

uniform backlighting of the sign and will provide simple mounting.

Remove tape backing and stick LED

modules into place. When using

tape apply approximately 15 psi

pressure on the module (avoid the

lens dome surface) for 5 seconds,

full bonding strength after 24 hours.

Continue until you have reached the

end of the strip.

Do not

press lens

Electrical Connections

Cap wires

Optional: Cut wires flush

Connect LED strips using in-line (IDC) connectors or

twist-on wire connectors.

Seal all connections in wet locations with electrical

grade RTV silicone.

Must cap all exposed wires with appropriate wire

connectors and seal with electrical grade RTV silicone.

Optional: Cut wires flush to the module and seal with

electrical grade RTV silicone.

Red stripe (+)

White (-)

Seal all connections in wet locations

with electrical grade RTV silicone

NOTE: Do not use connectors pre-filled with silicone grease/mineral base protective grease or use silicone grease to seal connections.

1

1

4

2

2

5

3

6

Tetra

®

PowerMAX

Installation Guide

4