4

Effective November 2016

Installation Instructions for TMQV

Circuit Breakers and Molded Case Switches

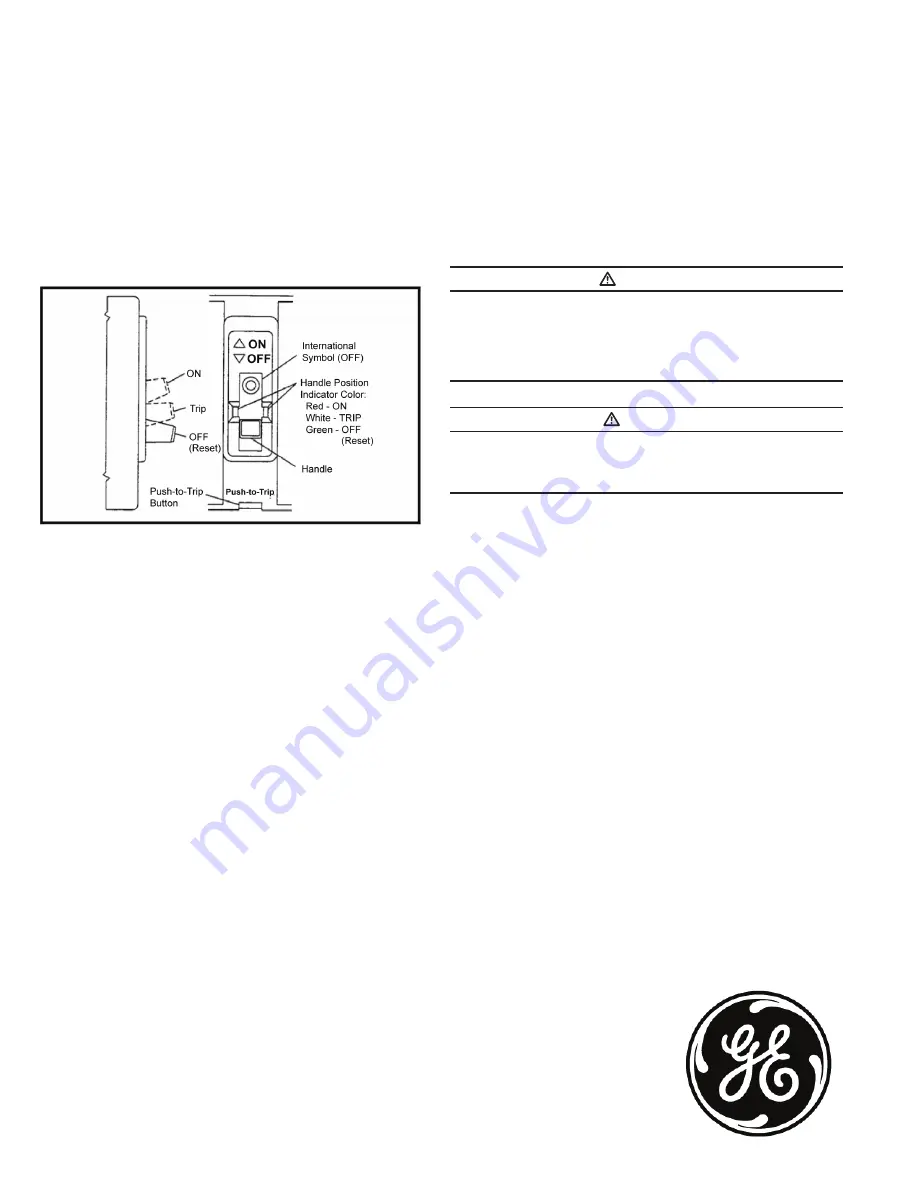

3. Manual Operation

Manual operation of the circuit breaker is controlled by the circuit

breaker handle and the PUSH-TO-TRIP button. The circuit breaker

handle has three indicated positions, two of which are shown on

the cover with raised lettering to indicate ON and OFF. On the slid-

ing handle barrier, ON, OFF, and trip are also shown by a color-coded

strip for each circuit breaker handle position: red for ON, white for

tripped, and green for OFF. On the sliding handle barrier, ON/OFF is

also shown with the international symbols I/0 (See Fig. 4.)

Figure 4. Circuit Breaker Manual Controls.

Circuit Breaker Reset

After tripping, the circuit breaker is reset by moving the circuit break-

er handle to the extreme OFF position.

ote:

N

In the event of a thermal trip, the circuit breaker cannot be reset until

the thermal element cools.

PUSH-TO-TRIP Button

The PUSH-TO-TRIP button checks the tripping function and is used

to periodically exercise the operating mechanism.

4. Inspection and Field Testing

TMQV molded case circuit breakers are designed to provide years

of almost maintenance-free operation. The following procedure

describes how to inspect and test a circuit breaker in service.

Inspection

Circuit breakers in service should be inspected periodically. The

inspection should include the following checks 4-1 thru 4-7.

WARNING

BEFORE INSPECTING THE CIRCUIT BREAKER IN AN ELECTRICAL

SYSTEM, MAKE SURE THE CIRCUIT BREAKER IS SWITCHED TO THE OFF

POSITION AND THERE IS NO VOLTAGE PRESENT WHERE WORK IS TO BE

PERFORMED. SPECIAL ATTENTION SHOULD BE PAID TO REVERSE FEED

APPLICATIONS TO ENSURE NO VOLTAGE IS PRESENT. THE VOLTAGES IN

ENERGIZED EQUIPMENT CAN CAUSE INJURY OR DEATH.

CAUTION

MAKE SURE THAT CLEANING AGENTS OR SOLVENTS USED TO CLEAN

THE CIRCUIT BREAKER ARE SUITABLE FOR THE JOB. SOME COMMERCIAL

CLEANING AGENTS WILL DAMAGE THE NAME PLATES OR MOLDED

PARTS.

4-1. Remove dust, dirt, soot, grease, or moisture from the surface

of the circuit breaker using a lint-free dry cloth, brush, or vacuum

cleaner. Do not blow debris into circuit breaker. If contamination is

found, look for the source and eliminate the problem.

4-2. Switch circuit breaker to ON and OFF several times to be sure

that the mechanical linkages are free and do not bind. If mechanical

linkages are not free, replace circuit breaker.

4-3. Press the PUSH-TO-TRIP button to mechanically trip the circuit

breaker. Trip, reset, and switch circuit breaker ON several times. If

mechanism does not reset each time the circuit breaker is tripped,

replace the circuit

4-4. Check base, cover, and operating handle for cracks, chipping,

and discoloration. Circuit breakers should be replaced if cracks or

severe discoloration is found.

4-5. Check terminals and connectors for looseness or signs of over-

heating. Overheating will show as discoloration, melting, or blister-

ing of conductor insulation, or as pitting or melting of conductor sur-

faces due to arcing. If there is no evidence of overheating or loose-

ness, do not disturb or tighten the connections. If there is evidence

of overheating, terminations should be cleaned or replaced. Before

re-energizing the circuit breaker, all terminations and cable should be

refurbished to the condition when originally installed.

4-6. Check circuit breaker mounting hardware. Tighten if necessary.

4-7. Check area where circuit breaker is installed for any safety haz-

ards, including personal safety and fire hazards. Exposure to certain

types of chemicals can cause deterioration of electrical connections.

Field Testing

Any field testing should be done in accordance with applicable

NEMA Standards.

DEH41188 Installation Instructions

GE

41 Woodford Ave.

Plainville, CT 06062

© 2016 General Electric Company

Information provided is subject to change without notice. Please verify all details with GE.

All values are design or typical values when measured under laboratory conditions, and GE makes no warranty

or guarantee, express or implied, that such performance will be obtained under end-use conditions.