GE Multilin

745 Transformer Management Relay

5-49

5 SETPOINTS

5.6 S4 ELEMENTS

5

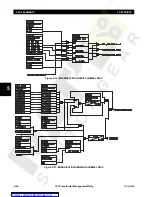

5.6.5 PHASE OVERCURRENT

a) MAIN MENU

PATH: SETPOINTS

ÖØ

S4 ELEMENTS

ÖØ

PHASE OC

This section contains settings to configure the phase overcurrent elements. Included are phase time overcurrents and two

levels of phase instantaneous overcurrent for each phase of each winding.

b) TIME OVERCURRENT CURVES

The inverse time overcurrent curves used by the TOC (time overcurrent) elements are the ANSI, IEC, and GE Type IAC

curve shapes. This allows for simplified coordination with downstream devices. If however, none of these curve shapes is

adequate, FlexCurves™ may be used to customize the inverse time curve characteristics. The Definite Time curve is also

an option that may be appropriate if only simple protection is required.

A time dial multiplier setting allows selection of a multiple of the base curve shape (where the time dial multiplier = 1) with

the curve shape (

SHAPE

) setting. Unlike the electromechanical time dial equivalent, operate times are directly proportional

to the time multiplier (

TIME OC MULTIPLIER

) setting value. For example, all times for a multiplier of 10 are 10 times the multi-

plier 1 or base curve values. Setting the multiplier to zero results in an instantaneous response to all current levels above

pickup.

Graphs of standard time-current curves on 11”

×

17” log-log graph paper are available upon request from

the GE Multilin literature department. The original files are also available in PDF format on the UR Software

Installation CD and the GE Multilin Web Page.

PHASE OC

[ENTER] for more

W1 PHASE TIME OC

[ENTER] for more

See page 5–53.

W2 PHASE TIME OC

[ENTER] for more

See page 5–53.

W3 PHASE TIME OC

[ENTER] for more

See page 5–53.

W1 PHASE INST OC 1

[ENTER] for more

See page 5–55.

W2 PHASE INST OC 1

[ENTER] for more

See page 5–55.

W3 PHASE INST OC 1

[ENTER] for more

See page 5–55.

W1 PHASE INST OC 2

[ENTER] for more

See page 5–55.

W2 PHASE INST OC 2

[ENTER] for more

See page 5–55.

W3 PHASE INST OC 2

[ENTER] for more

See page 5–55.

Table 5–4: TIME OVERCURRENT CURVE TYPES

ANSI

IEC

GE TYPE IAC

OTHER

ANSI Extremely Inverse

IEC Curve A (BS142)

IAC Extremely Inverse

FlexCurve™ A

ANSI Very Inverse

IEC Curve B (BS142)

IAC Very Inverse

FlexCurve™ B

ANSI Normally Inverse

IEC Curve C (BS142)

IAC Inverse

FlexCurve™ C

ANSI Moderately Inverse

IEC Short Inverse

IAC Short Inverse

Definite Time

ENTER

ESCAPE

ð

ð

MESSAGE

ESCAPE

MESSAGE

ESCAPE

MESSAGE

ESCAPE

MESSAGE

ESCAPE

MESSAGE

ESCAPE

MESSAGE

ESCAPE

MESSAGE

ESCAPE

MESSAGE

ESCAPE

NOTE