– 27 –

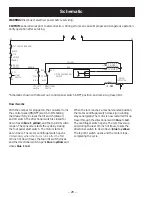

Motor Run Winding

1. Remove

the

blue wire from the start switch, and

the blue wires from the top limit switch and the

directional switch.

2. Connect an ohmmeter to the blue wire and

to the neutral side of the power cord. Proper

resistance is ~1.6 ohms. If the ohmmeter shows

an open circuit, either the run winding or the

motor protector is open and the motor must be

replaced.

Motor Centrifugal Switch

1. Disconnect the wires from the motor centrifugal

switch.

2. Connect an ohmmeter to the terminals.

3. The ohmmeter should read 1 ohm or less. If

the circuit is open, the motor switch is stuck or

burned, and the motor must be replaced.

Jammed Ram

1. Check for 120 Volts at the outlet.

2. If the drawer is open, push in on the drawer.

3. If the ram does not come up, unplug the

compactor.

a. Open motor rear cover plate.

b. Rotate the motor shaft in the counter-

clockwise direction, using a 1/4 in. hex

socket screw key (hex wrench) to make the

ram go up.

Chain Adjustment

There should be 3/8 in. (9.5 mm) to 1/2 in. (12.7 mm)

GHÀHFWLRQEHWZHHQDQ\VSURFNHWV

Lubrication

• Power

Screws: If needed, apply WC32X5004

grease to the Ram Screws.

• Drawer Slide Rollers: Apply WC01X10006

oil.

“Not Compacting” Complaints

• Low

Voltage: Check supply voltage with

the ram compacting trash. At 120 volts ram

force is approximately 2300 lbs. At voltage

lower than 120 volts ram force is reduced.

• Ram

Travel: Ram stops 7-1/2 in. (190 mm)

above the bottom of the container. No

noticeable compaction will occur until the

container is 1/2 full.

NOTE: For best compacting results, do not

overload the compactor container. Cycle the unit

frequently. No compaction will occur if too much

WUDVKERWWOHVFDQVHWFLVDGGHGDWRQHWLPH

Overloading may exceed the crushing force of the

ram. A spongy trash load may prevent bottles from

breaking. Most, but not all, bottles in a trash load will

be broken.