GE Multilin

L90 Line Current Differential System

5-293

5 SETTINGS

5.7 CONTROL ELEMENTS

5

To distinguish between single-phase disappearance and system disturbance in all three phases (such as load change,

switching, etc.), the broken conductor element monitors the change in all three phase currents at the present instance and

at four cycles previous. It also monitors changes in the I_2 / I_1 ratio, I_1 minimum, and I_1 maximum.

The broken conductor function should not be used to respond to fault transients and single-pole tripping/reclosing condi-

tions. Therefore, the time delay should be programmed to a sufficient length to ensure coordination with the breaker dead

time of the recloser function.

•

BROKEN CONDUCTOR 1 FUNCTION

: This setting enables and disables the broken conductor function.

•

BROKEN CONDUCTOR 1 SOURCE

: This setting selects a signal source used to provide three-phase current inputs

to this function.

•

BROKEN CONDUCTOR 1 I2/I1 RATIO

: This setting specifies the ratio of negative-sequence current to positive-

sequence current. When one phase conductor is broken, the I_2 / I_1 ratio with a balanced remaining two phases is

50%. So normally this setting should be set below 50% (for example, to 30%).

•

BROKEN CONDUCTOR 1 I1 MIN

: This setting specifies the minimum positive-sequence current supervision level.

Ensure this setting is programmed to a sufficient level to prevent I_2 / I_1 from erratic pickup due to a low I_1 signal.

However, this setting should not be set too high, since the broken conductor condition cannot be detected under light

load conditions when I_1 is less than the value specified by this setting.

•

BROKEN CONDUCTOR 1 I1 MAX

: This setting specifies the maximum I_1 level allowed for the broken conductor

function to operate. When I_1 exceeds this setting, this it is considered a fault. This broken conductor function should

not respond to any fault conditions, so normally this setting is programmed to less than the maximum load current.

•

BROKEN CONDUCTOR 1 PKP DELAY

: This setting specifies the pickup time delay for this function to operate after

assertion of the broken conductor pickup FlexLogic operand.

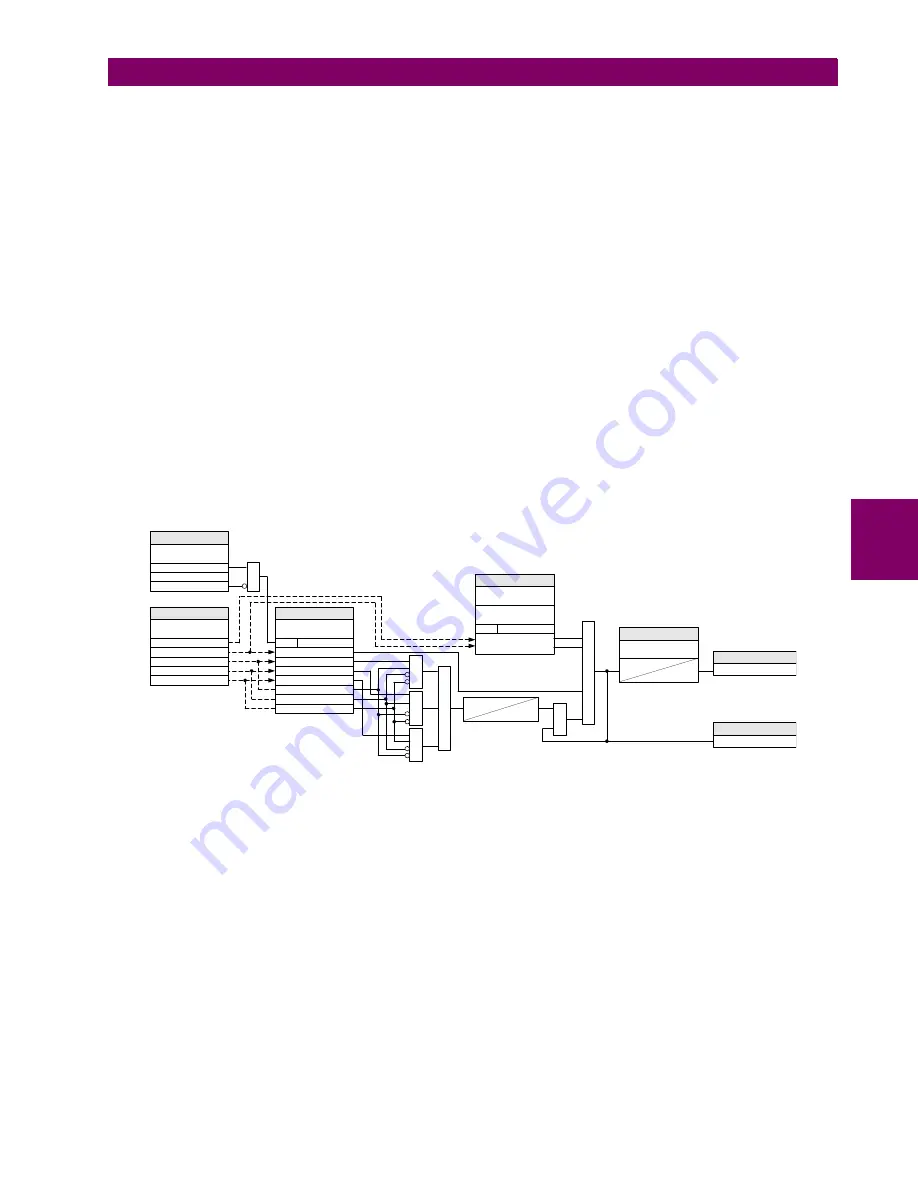

Figure 5–158: BROKEN CONDUCTOR DETECTION LOGIC

SETTINGS

BROKEN CONDUCTOR 1

FUNCTION:

Enabled = 1

AN

D

BROKEN CONDCT 1 BLK:

Off = 0

SETTINGS

BROKEN CONDUCTOR 1

SOURCE:

I2

FLEXLOGIC OPERAND

BROKEN CONDUCT 1

OP

I1

Ia

Ib

Ic

AN

D

SETTING

BROKEN CONDUCTOR 1

I1 MIN :

| I1 | > I1 MIN

| Ia | < I1 MIN

| Ib | < I1 MIN

| Ic | < I1 MIN

| Ia’ | - | Ia | > 0.05pu

| Ib’ | - | Ib | > 0.05pu

| Ic’ | - | Ic | > 0.05pu

Where I’ is 4 cycles old

AN

D

AND

OR

One phase current loss

detection

RUN

2 cyc

0

AN

D

OR

SETTING

BROKEN CONDUCTOR 1

I1 MAX :

RUN

| I1 | < I1 MAX

| I2 | / | I1 |> RATIO

BROKEN CONDUCTOR 1

I2/I1 RATIO :

t

PKP

0

SETTING

BROKEN CONDUCTOR 1

I1 MAX :

FLEXLOGIC OPERAND

BROKEN CONDUCT 1

PKP

Summary of Contents for UR Series L90

Page 652: ...A 16 L90 Line Current Differential System GE Multilin A 1 PARAMETER LISTS APPENDIX A A ...

Page 772: ...B 120 L90 Line Current Differential System GE Multilin B 4 MEMORY MAPPING APPENDIX B B ...

Page 802: ...C 30 L90 Line Current Differential System GE Multilin C 7 LOGICAL NODES APPENDIX C C ...

Page 812: ...D 10 L90 Line Current Differential System GE Multilin D 1 IEC 60870 5 104 APPENDIX D D ...

Page 824: ...E 12 L90 Line Current Differential System GE Multilin E 2 DNP POINT LISTS APPENDIX E E ...

Page 834: ...F 10 L90 Line Current Differential System GE Multilin F 3 WARRANTY APPENDIX F F ...

Page 846: ...xii L90 Line Current Differential System GE Multilin INDEX ...