5-66

L90 Line Current Differential System

GE Multilin

5.2 PRODUCT SETUP

5 SETTINGS

5

c) TRIP AND ALARM LEDS

PATH: SETTINGS

PRODUCT SETUP

USER-PROGRAMMABLE LEDS

TRIP & ALARM LEDS

The trip and alarm LEDs are in the first LED column (enhanced faceplate) and on LED panel 1 (standard faceplate). Each

indicator can be programmed to become illuminated when the selected FlexLogic operand is in the logic 1 state.

d) USER-PROGRAMMABLE LED 1(48)

PATH: SETTINGS

PRODUCT SETUP

USER-PROGRAMMABLE LEDS

USER-PROGRAMMABLE LED 1(48)

There are 48 amber LEDs across the relay faceplate LED panels. Each of these indicators can be programmed to illumi-

nate when the selected FlexLogic operand is in the logic 1 state.

For the standard faceplate, the LEDs are located as follows.

•

LED Panel 2: user-programmable LEDs 1 through 24

•

LED Panel 3: user programmable LEDs 25 through 48

For the enhanced faceplate, the LEDs are located as follows.

•

LED column 2: user-programmable LEDs 1 through 12

•

LED column 3: user-programmable LEDs 13 through 24

•

LED column 4: user-programmable LEDs 25 through 36

•

LED column 5: user-programmable LEDs 37 through 48

Refer to the

LED indicators

section in chapter 4 for additional information on the location of these indexed LEDs.

The user-programmable LED settings select the FlexLogic operands that control the LEDs. If the

LED 1 TYPE

setting is “Self-

Reset” (the default setting), the LED illumination will track the state of the selected LED operand. If the

LED 1 TYPE

setting is

“Latched”, the LED, once lit, remains so until reset by the faceplate RESET button, from a remote device via a communica-

tions channel, or from any programmed operand, even if the LED operand state de-asserts.

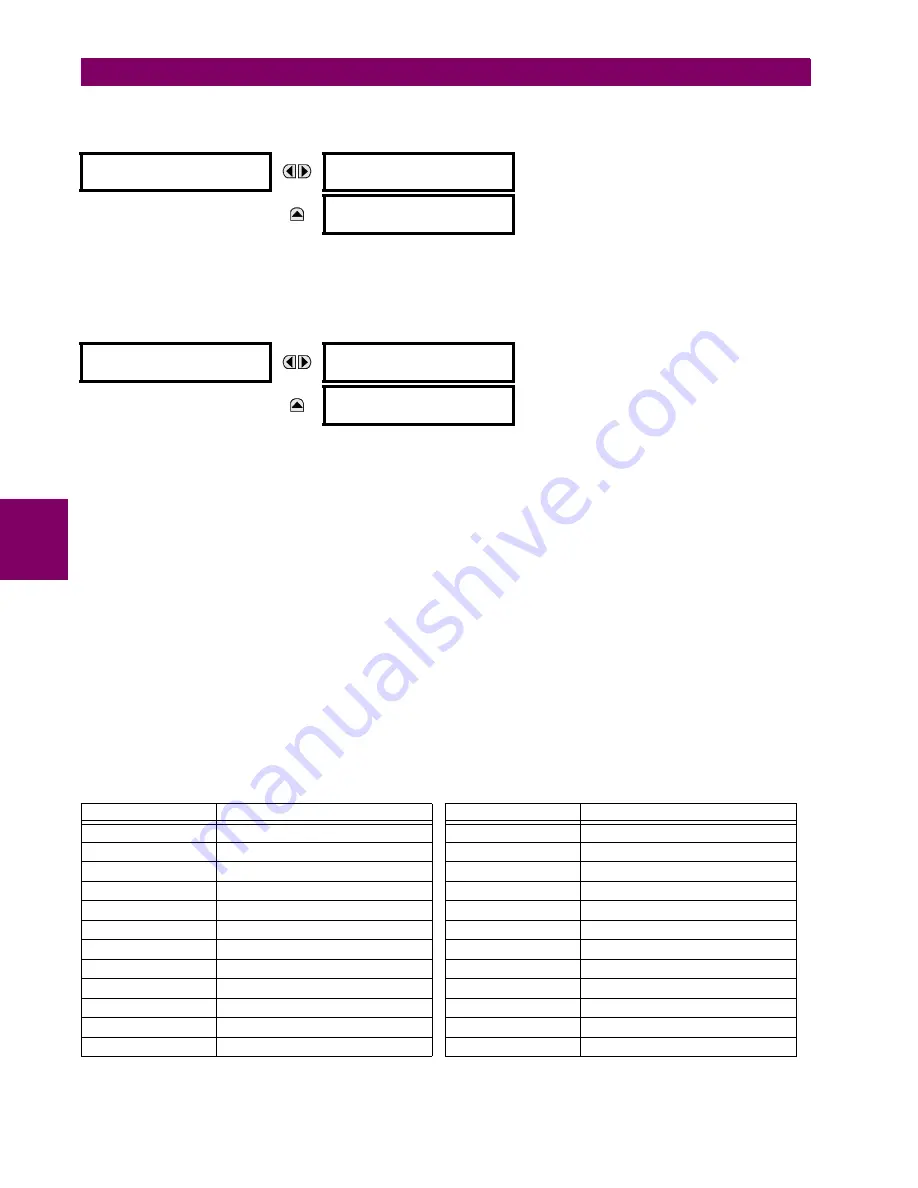

TRIP & ALARM LEDS

TRIP LED INPUT:

Off

Range: FlexLogic operand

MESSAGE

ALARM LED INPUT:

Off

Range: FlexLogic operand

USER-PROGRAMMABLE

LED 1

LED 1 OPERAND:

Off

Range: FlexLogic operand

MESSAGE

LED 1 TYPE:

Self-Reset

Range: Self-Reset, Latched

Table 5–6: RECOMMENDED SETTINGS FOR USER-PROGRAMMABLE LEDS

SETTING

PARAMETER

SETTING

PARAMETER

LED 1 operand

SETTING GROUP ACT 1

LED 13 operand

Off

LED 2 operand

SETTING GROUP ACT 2

LED 14 operand

BREAKER 2 OPEN

LED 3 operand

SETTING GROUP ACT 3

LED 15 operand

BREAKER 2 CLOSED

LED 4 operand

SETTING GROUP ACT 4

LED 16 operand

BREAKER 2 TROUBLE

LED 5 operand

SETTING GROUP ACT 5

LED 17 operand

SYNC 1 SYNC OP

LED 6 operand

SETTING GROUP ACT 6

LED 18 operand

SYNC 2 SYNC OP

LED 7 operand

Off

LED 19 operand

Off

LED 8 operand

Off

LED 20 operand

Off

LED 9 operand

BREAKER 1 OPEN

LED 21 operand

AR ENABLED

LED 10 operand

BREAKER 1 CLOSED

LED 22 operand

AR DISABLED

LED 11 operand

BREAKER 1 TROUBLE

LED 23 operand

AR RIP

LED 12 operand

Off

LED 24 operand

AR LO

Summary of Contents for UR Series L90

Page 652: ...A 16 L90 Line Current Differential System GE Multilin A 1 PARAMETER LISTS APPENDIX A A ...

Page 772: ...B 120 L90 Line Current Differential System GE Multilin B 4 MEMORY MAPPING APPENDIX B B ...

Page 802: ...C 30 L90 Line Current Differential System GE Multilin C 7 LOGICAL NODES APPENDIX C C ...

Page 812: ...D 10 L90 Line Current Differential System GE Multilin D 1 IEC 60870 5 104 APPENDIX D D ...

Page 824: ...E 12 L90 Line Current Differential System GE Multilin E 2 DNP POINT LISTS APPENDIX E E ...

Page 834: ...F 10 L90 Line Current Differential System GE Multilin F 3 WARRANTY APPENDIX F F ...

Page 846: ...xii L90 Line Current Differential System GE Multilin INDEX ...