– 21 –

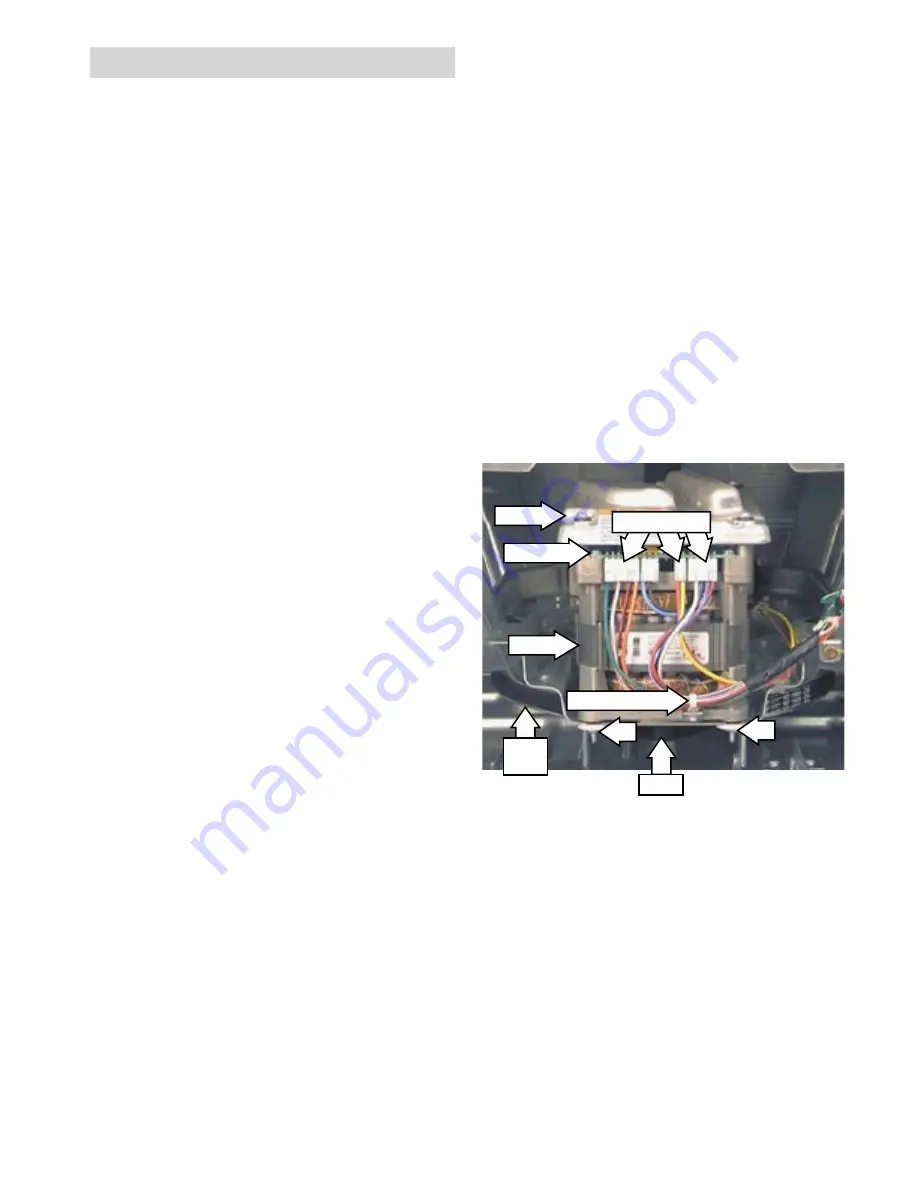

Inverter/Motor

The inverter/motor assembly receives 120 VAC,

which the inverter converts to approximately 340

VDC. The inverter then uses pulse width modulation

(PWM) to supply the motor with an AC varying

frequency to control speed.

Note:

There is no location to check inverter output

voltage to the motor. Voltage given is for information

only.

The inverter/motor assembly consists of a motor

and inverter board. A brake resistor is molded into

the underside of the inverter cover and absorbs

energy from the reversing of the motor during the

braking cycle. A Hall effect sensor mounted on the

inverter board measures motor speed (RPM).

The motor and inverter are available only as an

assembly.

WARNING:

Do not attempt to remove the inverter

cover to service the board or brake resistor.

Note:

• There is a non-resettable fuse, located in the

motor harness along the right side of the cabinet.

If the fuse is open, agitate, spin and mode shifting

will not occur. LED will not light.

• If the motor speed sensor fails, the motor will not

run. LED will flash.

• Since the timer receives no feedback from the

inverter motor assembly and if the motor is not

operating, the washer will still fill with water, count

down on the display and drain.

• If during an agitation cycle, water leaks from the

tub and resets the pressure switch,

the inverter

control stops agitation and goes through the

mode shifter spin program to de-energize the

cam and the washer starts to refill with water. The

motor will not run again until the pressure switch

is satisfied, at which time the inverter control will

run the mode shifter agitate program.

• If the mode shifter circuit fails or the coil opens,

the tub will move back and forth with the agitator

during the wash cycle.

To remove the inverter/motor:

Disconnect power.

WARNING:

Exposed terminals, PC board, and

rotating parts may cause injury and/or electrical

shock. To reduce the risk of electrical shock,

disconnect power and allow at least 5 minutes for

capacitors to discharge before servicing motor.

An audible clicking sound will be heard when the

inverter capacitor discharges (in-rush relay closing).

Remove the front panel. (See

Front Panel

.)

Disconnect 3 wire harnesses from the motor.

Release the compression tabs that attach the

wire retainer to the front of the platform.

Remove the belt by rolling it off the bottom of the

motor pulley.

Remove the front two 3/8" motor nuts and loosen

the rear 2 nuts.

1.

2.

3.

4.

5.

6.

(Continued next page)

Cover

Inverter

Motor

Wire Retainer

Belt

Drive

Pully

Disconnect