– 28 –

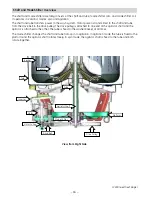

Lift the shaft and mode shifter assembly from

the platform.

13.

Shaft and Mode

Shifter Assembly

Remove the inverted single 3/8" hex-head bolt

from the top of the platform.

Note:

Torque the four 3/8" hex-head bolts to 90 in.

lbs. when reinstalling.

12.

Inverted Bolt

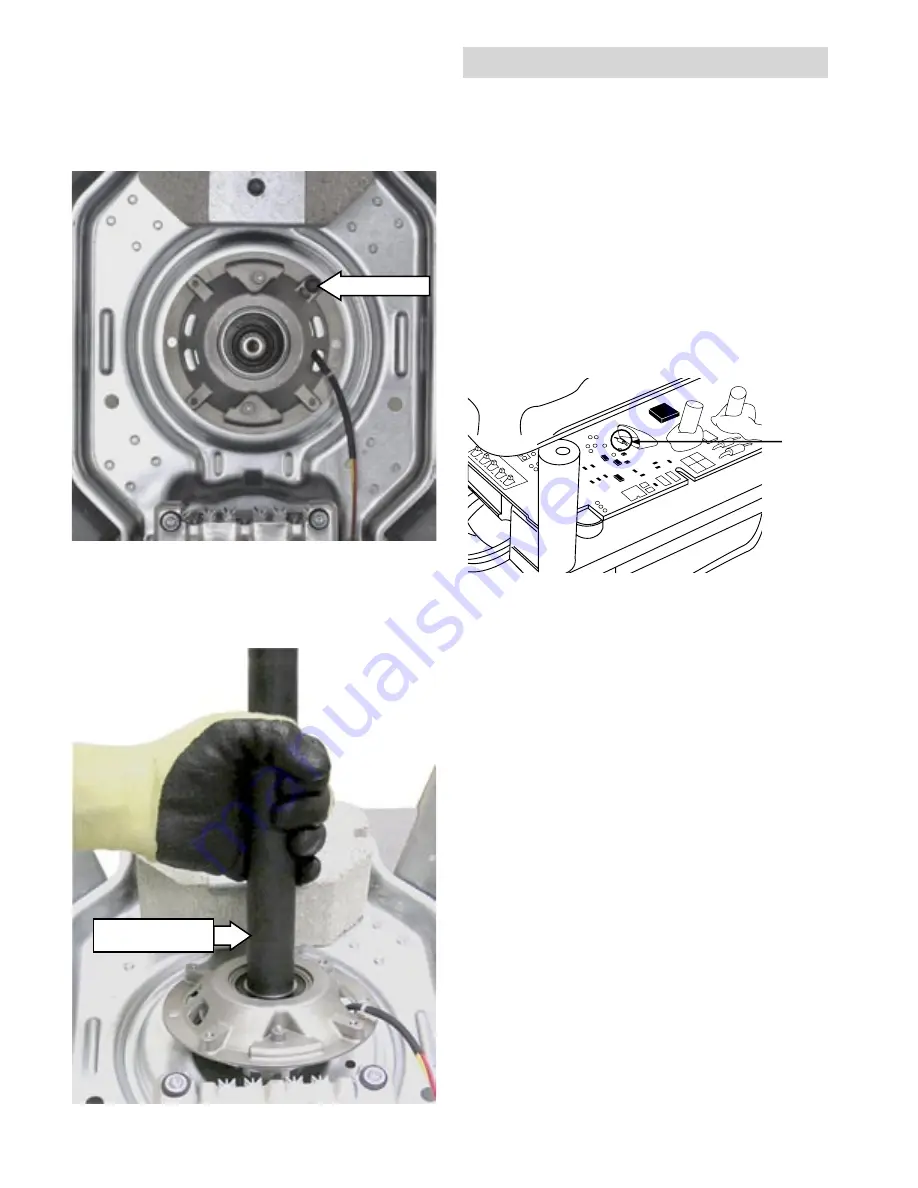

Inverter/Motor Signal LED

•

An LED beneath the inverter cover can be viewed

for diagnostic testing. (It is best viewed from the

right side of the motor.)

•

When Motor is operating normally, and running,

the LED blinks at a constant rate of 1/2 second

on and 1/2 second off.

•

When Motor is operating normally, and idle, the

LED blinks at a constant rate of 1 second on and

1 second off.

•

Motor/control error condition – LED is on for .25

seconds and off for .25 seconds for a specified

number of times, during a 6-second period. The

6-second cycle repeats continuously.

(Continued next page

)

LED is

green

light