D

GB

F

E

I

21

96389-08.2019-DGbFEIRu

Fig. 18

5

|

Electrical connection

5.1 Potential equalization

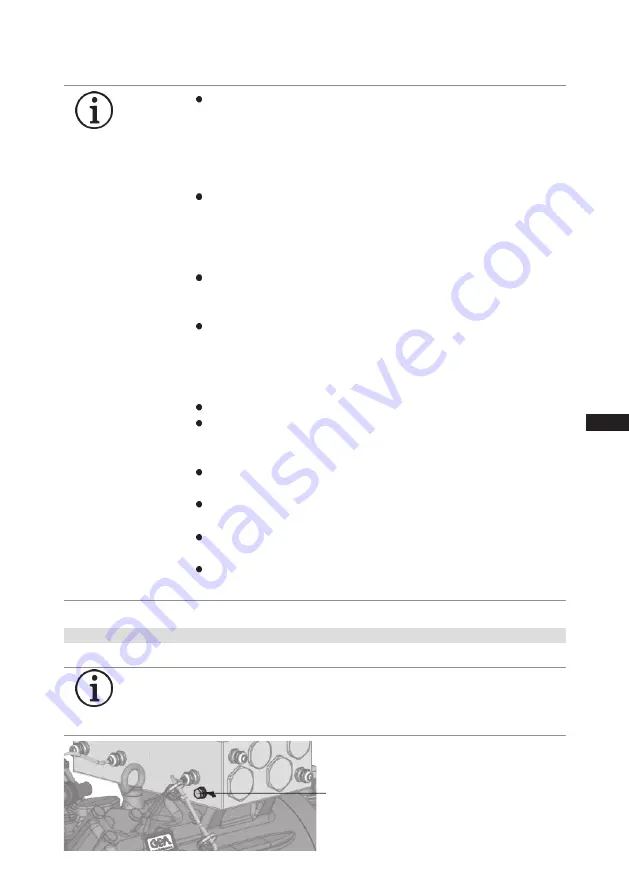

Before start-up, the potential equalisation must be connected (see Fig. 18).

Potential equalization connection

INFO

Special attention must be paid to sufficient conductivity of all contact

points. There must be a large seat (e.g. with ring cable lug).

The installed voltage equalization must be secured against loosing

and firmly connected to earth

INFO

Connect the compressor motor according to the circuit diagram

(s. fig. 19-21

or sticker inside the terminal box). Comply with local safety reg-

ulations for electrical work, safety standards (within the EU:

EN 60204, EN 60335 among others) and regulations for setting up

electrical systems in explosion-endangered areas (within the EU: IEC/

EN 60079-14 among others).

Avoid damage to cable fittings, since otherwise operational safety can

be impaired. Lay the cable so that the fitting to the terminal box will

not loosen itself. If necessary (e.g. installation that is not twist free),

protection against loosening can be achieved through check nuts or

appropriate adhesive. Avoid abrasion points on cables.

For cable lead-through at the terminal box, use suitable Ex cable

screw connections in the correct protective version (see name plate).

Use strain relief. Avoid abrasion points on cables.

Install all switching devices outside the explosion-endangered area.

Motor contactors, feed lines and fuses are to be rated according to the

maximum operating current (see name plate). Recommendations for

contactor and motor protection selection are included in the table at

the end of the „Electrical system“ chapter 5.2.

Do not separate contacts 1 + 2 of the motor thermistors under voltage.

Compare the details for voltage and frequency on the nameplate with

the details for the electricity mains supply. The motor may only be

connected if these details match.

Use a motor protector switch. It should be set to the rated motor current

and checked.

For the installation of phases L1, L2 and L3 to line-up terminals U1, V1

and W1,

no

solid wire may be used.

Cross section for connection of line-up terminals L1, L2 and L3 =

6 - 35 mm².

Cross section for connection of line-up terminals 1, 2, 3 and 4 =

max. 2.5 mm².