16

D

GB

F

E

I

96463-08.2019-DGbFEIRu

4

|

Compressor assembly

4.1 Ignition source control of the compressor

INFO

•

New compressors are factory-filled with inert gas. Leave this ser

-

vice charge in the compressor for as long as possible and prevent

the ingress of air.

•

Check the compressor for transport damage before starting any

work.

•

Before starting work, obtain written work release.

•

Observe national regulations when setting up explosion-protected

systems (within the EU: ATEX Directive 1999/92/EG, EN 60079-14,

EN 60079-17 a.o.).

•

Use only tools permitted for explosion-protected systems (within

the EU, in accordance with EN 1127-1).

•

Observe work safety rules (TRGS 727, e.g. protective shoes,

clothing etc.)!

To protect against an exceeding of temperature the protection type ignition source control "b" is

used at the compressor. Via sensors, the areas with the highest heat potential at every cylinder

cover are controlled. Additionally, the temperature of the motor winding is controlled by the safety

device INT69 EX2.

The permissible limit temperatures for normal operation of the compressor were set with 130 °C for

the motor and with 140 °C for the hot gas side of the cylinder cover. If one of those values is exceeded,

the compressor is shut down by the control device INT69 EX2. Besides the installation according to

wiring diagram, the operator

/

installer does not have to regard other parameters for the correct func-

tioning of the ignition protection system. A function check however has to be carried out before every

startup of the compressor according to section 5.10 of this assembly instruction.

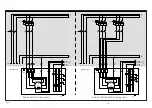

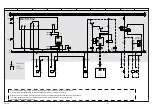

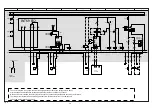

For a safe function of the ignition source control the INT69 EX2 has to be installed according to the

wiring diagrams fig. 20 and 21. Check the function of the ignition protection system according to sec

-

tion 5.10. Defective sensors or ignition protection systems have to be replaced before reconnection

of the compressor.

Operation of the compressor without ignition source control is not permitted!

After shutdown by the INT69 EX2, precise error diagnostics and error correction is necessary.

The INT69 EX2 has a restart interlock that can only be interrupted by means of voltage inter-

ruption.