2

D

GB

F

E

96031-11.2011-DGbFEI

1

Safety

4

1.1 Identification of safety instructions

1.2 Qualifications required of personnel

1.3 General safety instructions

1.4 Intended use

2

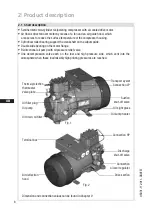

Product description

6

2.1 Short description

2.2 Name plate

2.3 Type key

3

Areas of application

8

3.1 Refrigerants

3.2 Oil charge

3.3 Limits of application

4

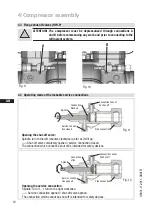

Compressor assembly

9

4.1 Setting up

4.2 Pipes

4.3 Flange shut-off valves (HP/LP)

4.4 Operating mode of the lockable service connections

4.5 Operating the shut-off valves

4.6 Pipe connections

4.7 Laying suction and pressure lines

5

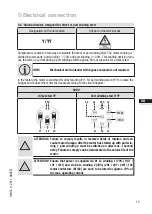

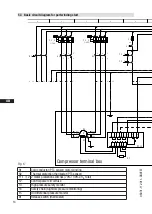

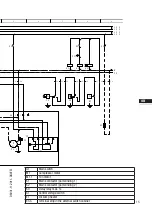

Electrical connection

12

5.1 Information for contactor and motor contactor selection

5.2 Standad motor, designed for direct or part winding start

5.3 Maine line wiring diagram for part winding

5.4 Electronic trigger unit MP 10

5.5 Connection of the electronic trigger unit MP 10

5.6 Functional test of the electronic trigger unit MP 10

5.7 Oil sump heater

5.8 Fan motor

6

Commissioning

18

6.1 Preparations for start-up

6.2 Pressure strength test

6.3 Leak test

6.4 Evacuation

6.5 Refrigerant charge

6.6 Start-up

6.7 Decompression valves

6.8 Avoiding slugging

7

Maintenance

22

7.1 Preparation

7.2 Work to be carried out

7.3 Spare parts recommendation

7.4 Accessories

7.5 Decommissioning

8

Technical data

24

9

Dimensions and connections

25

10 Declaration of conformity and installation

26

11 Service

27

About these instructions

Read these instructions before assembly and before using the compressor. This will avoid misunder

-

standings

and prevent damage. Improper assembly and use of the compressor can result in serious

or fatal injury.

Observe the safety instructions contained in these instructions.

These instructions must be passed onto the end customer along with the unit in which the compres

-

sor is installed.

GEA Bock GmbH

72636 Frickenhausen

GEA Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

Tel49 7022 9454 0

Fax

+49 7022 9454 137

mail@bock.de

www.bock.de

Manufacturer

Contact