GB

GB

F

E

19

96438-02.2020-DGbRu

6.4 Shaft seal change

As changing the shaft seal involves opening the refrigerant circuit, this is recommended only if the

seal is losing refrigerant. Replacing the shaft seal is described in the spare part kit concerned.

WARNING

Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from infiltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.

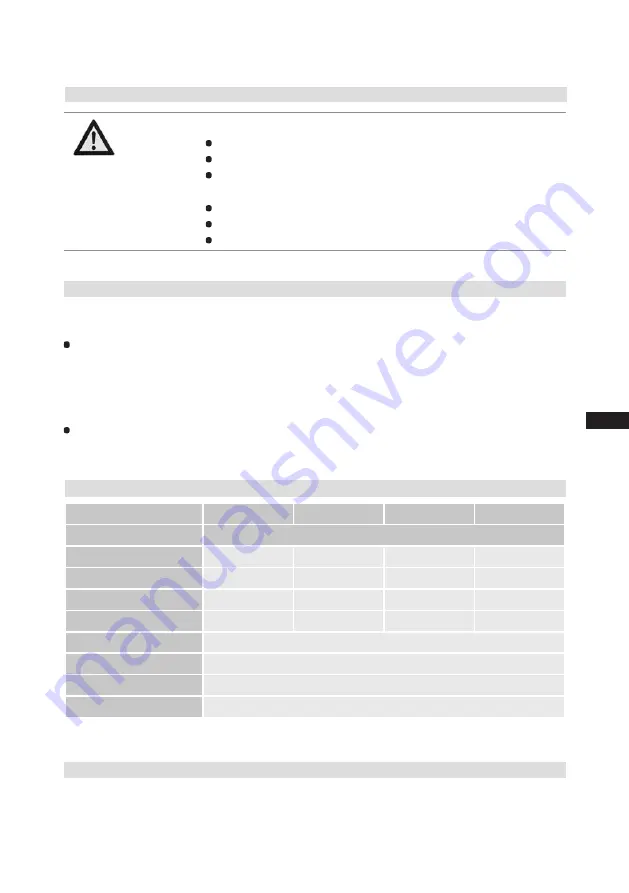

F76 / ...

1570

1800

2050

2425

Designation

Ref. No.

Set of gaskets

81303

81304

81305

81306

Valve plate kit

81616

81617

81743

81744

Kit piston / connecting rod

81287

81288

08491

81290

Kit capacity regulator

80879

81414

80889

80879

Oil pump kit

80116

Kit shaft seal

80897

Oil SP 46, 1 litre

02279

Oil SE 55, 1 litre

02282

6.3 Spare parts recommendation

Only use genuine GEA Bock spare parts!

6

|

Maintenance

6.1 Preparation

6.2

Work to be carried out

To guarantee optimum operating safety and service life of the compressor,

we recommend

perform-

ing service and checking work at regular intervals of time:

Oil change:

-

In series plants produced in the factory not mandatory.

-

In field installations or operating in the application limit range, first oil change after approx.

100 - 200 operating hours, then approx. every 3 years or 10,000 - 12,000 operating hours.

Dispose of old oil according to the regulations, observe national regulations.

Annual checks:

Oil level, tightness, running noise, pressures, temperatures, function of auxiliary

devices such as a oil sump heater, pressure switch. Comply with the national regulations!