D

GB

F

E

25

96416-08.2020-DGbFEIRu

7

|

Electrical connection

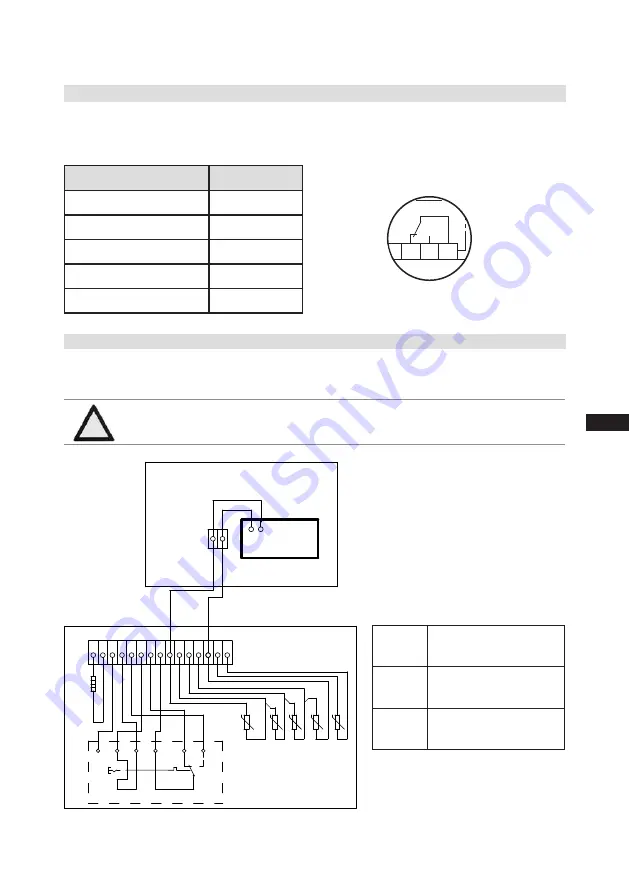

Relay position INT69 G

B2 12 14 11

Fig. 14

Fig. 15

7.8

Function test of the trigger unit INT69 G

Before commissioning, after troubleshooting or making changes to the control power circuit, check

the functionality of the trigger unit. Perform this check using a continuity tester or gauge.

Gauge state

Relay position

Deactivated state

11-12

INT69 G switch-on

11-14

Remove PTC connector

11-12

Insert PTC connector

11-12

Reset after mains on

11-14

7.9

Electronic trigger unit INT69 G at HC and LG compressors

The supplied INT69 G must be connected according to the wiring diagram shown here in a separate

control cabinet, which must be installed outside each danger zone.

BT1

Cold conductor (PTC

sensor) motor winding

BT2

Heat protection thermo

-

stat (PTC sensor)

EB1

Oil sump heater

ATTENTION

Install heat protection thermostats and cold conductor motor

winding in series!

Οnderung

2

0

Datum

Name

Datum

Bearb.

Gepr.

Norm

1

04.12.2009

bauknecht

08.05.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

HG44e/56e HC

5

6

7

BOCK COMPRESSORS

8

=

+

9

Bl.

5

Bl.

4

3

DELTA- P II

Schaltschrank

EB1

BT2

BT2

BT1

vio

bn

bu

gr

og

pk

1 2 3 4 5 6 7 8

10 11 12

INT69G

BT2

13 20 21

09

Öl-Temp.

Οnderung

2

0

Datum

Name

Datum

Bearb.

Gepr.

Norm

1

04.12.2009

bauknecht

08.05.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

HG44e/56e HC

5

6

7

BOCK COMPRESSORS

8

=

+

9

Bl.

5

Bl.

4

3

DELTA- P II

Schaltschrank

EB1

BT2

BT2

BT1

vio

bn

bu

gr

og

pk

1 2 3 4 5 6 7 8

10 11 12

INT69G

BT2

13 20 21

09

Öl-Temp.

Switch cabinet

Summary of Contents for Bock HG44e/475-4

Page 41: ......