30

D

GB

F

E

I

Ru

09790-02.2018-DGbFEIRu

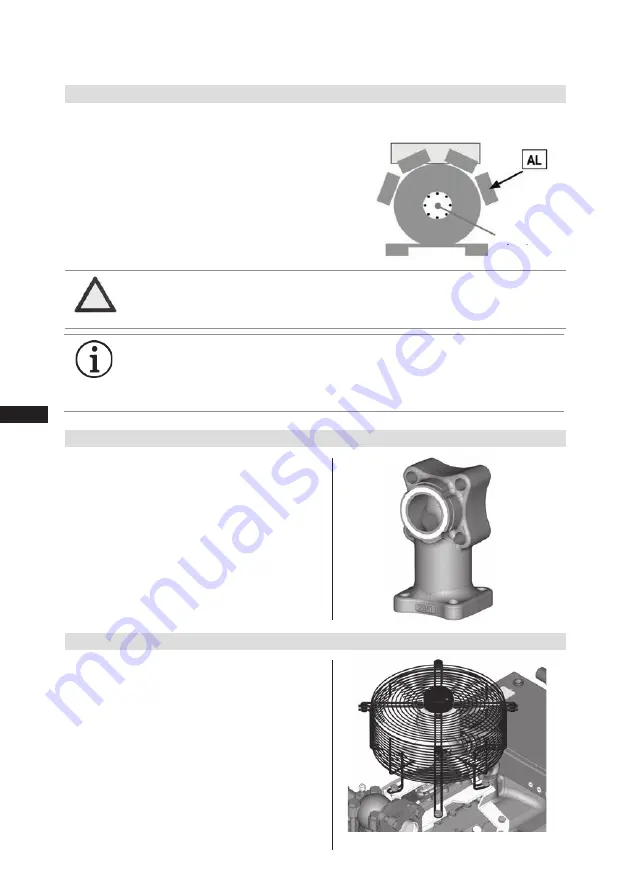

A start unloader is necessary for Y/

Δ

start (special motor).

• Fit the non-return valve in the discharge pipe

• Rate the non-return valve according to the

operating conditions.

• Electrical trigger for the solenoid valve:

closed idle

• Cylinder cover for start unloader is marked

„SU“ (start unloader)

8.1 Start unloader (kit-Item No. 08981)

8

|

Accessories

8.2 Intermediate adapter for discharge line valve (Item No. 04362)

The adapter for the discharge line valve can be used

to move the compressor discharge gas connection

upwards. This makes it easier to remove the

compressor from a refrigerating plant.

8.3 Additional fan (Item No. 80270)

When the HG8 compressor is used in the deep-

freeze range, the application limits can be extended

by additional cooling if the cylinder heads (see

limits of application diagramms). The kit contains

all necessary fastening parts for mounting on the

cylinder covers.

Fig. 25

Fig. 26

Fig. 27

Oil pump

ATTENTION

The start unloader must only run during the start-up phase, approx.

5 seconds before to max. 5 seconds after the compressor starts.

Otherwise there is a risk of overheating from bypass operation.

INFO

A start unloader is not required for part winding start (PW start,

standard motor). But the start-up current for part winding start

can be reduced by an additional 10 % by using a mechanical start

unloader