D

GB

F

E

11

96458-03.2019-DGb

4

|

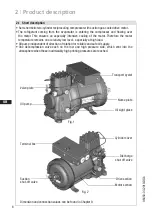

Compressor assembly

Material soldering / welding connection: S235 (JRG2C)

The

pipe connections

have graduated inside diameters so that pipes with

standart millimetre and inch dimensions can be used.

The connection diameters of the shut-off valves are rated for maximum

compressor output.

The actual required pipe cross section must be

matched to the output. The same applies for non-return valves.

Fig. 11: graduated

internal diameter

4.3 Connecting the pipelines - solder system

ATTENTION Damage possible.

Superheating can damage the valve.

Remove the pipe supports therefore from the valve for soldering

and accordingly cool the valve body during and after soldering.

Only solder using inert gas to inhibit oxidation products (scale).

•

On its high-pressure side, the compressor has a shut-off valve with multi-sided cutting ring for safe

installation of the discharge line.

Cutting ring function before tightening the union nut

4.4 Connecting the pipelines - cutting ring system

Tube preparation:

The tube has to be sawn in a right angle. An angular tolerance of ±1° is permissible.

Slightly trim the pipe ends inside and outside. For thin walled steel pipes or soft pipes made of

nonferrous metal, reinforcing sleeves have to be used.

Pipe assembly:

Push Union Nut (5) and Cut Ring (3) onto Pipe (2). Insert pipe into Socket (6) as far as it will go and

firmly press against pipe stop, otherwise incorrect assembly. Hand tighten union nut until socket,

cutting ring and union nut are locked. Tighten union nut 1

1/2

turns using a spanner wrench. The

cutting ring is noticeably locked to the socket face (for assembly inside pipe connection, hold up valve

with a spanner wrench). This should cause the cutting ring with its cutting edges to cut into the pipe

resulting in a visible collar. In order to stick to the turns we recommend using marking lines on union

nut and pipe. After assembly, it is necessary to check the collar. The gasket must not be damaged.

At least 80 % of the cutting face has to be covered. After check-up, screw on and tighten again as

described above.

Fig. 12

Figure similar

.

.

.

.

.

Collar

Summary of Contents for Bock HGX2 CO2 T Series

Page 33: ...D GB F E 33 96458 03 2019 DGb ...