19

09740-06.2016-DGbFIT

r

D

GB

F

I

TR

6.5 Decommissioning

6.6 Valve plate, TK version

Close the shut-off valve on the compressor. Drain the refrigerant (it must not be discharged directly

into the environment) and dispose of it according to the regulations. When the compressor is

depressurised, undo the fastening screws of the shut-off valves. Remove the compressor using an

appropriate hoist. Dispose of the oil inside in accordance with the valid national regulations.

Based on the tried-and-tested N valve plate system, a valve plate with reduced dead space

has been adapted to the FK20 TK specifically for applications in the deep-freeze area. The system is

equipped with a non-interchange safeguard to avoid confusing it with N valve plate.

6

|

Maintenance

6.4 Extract from the lubricants table

The oil type charged as standard in the factory is marked on the

name plate

.

This oil type should be

used as a preference.

Alternatives are stated in the extract from our lubricants table below.

Refrigerants

GEA standard oil types

Recommended alternatives

HFC

(e.g. R134a, R407,

R 404A)

Fuchs Reniso Triton SE 55

(see also chap. 6.3)

Fuchs SEZ 32/68/80

Esso/Mobil EAL Arctic 46

HCFC

(e.g. R22)

Fuchs Reniso SP 46

(see also chap. 6.3)

BP Energol LPT 46

Sunoco Suniso 3.5GS

Texaco Capella WF 46

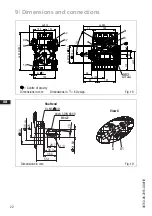

Non-interchange safeguard for the FK20 valve plate, TK version:

Fig. 17