23

09740-06.2016-DGbFIT

r

D

GB

F

I

TR

9

|

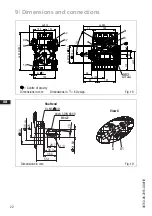

Dimensions and connections

SV

DV

Suction line

Discharge line see technical data, Chapter 8

A

Connection suction side, not lockable

7/16" UNF

A1

Connection suction side, lockable

7/16" UNF

A2

Connection suction side, not lockable

1/8" NPTF

B

Connection discharge side, not lockable

7/16" UNF

B1

Connection discharge side, lockable

7/16" UNF

B2

Connection discharge side, not lockable

1/8" NPTF

F

Oil drain plug

G 1/8"

G

Opt. connection for oil sump heating

1)

H

Oil charge plug

1/4" NPTF

K

Sightglass

2)

1)

= No connection available as standard.

Available on request (Connection M22 x 1.5)

2)

= No connection available as standard without sightglass.

Available on request (Connection M20 x 1)