37

09665

-0

8.

20

18-

Gb

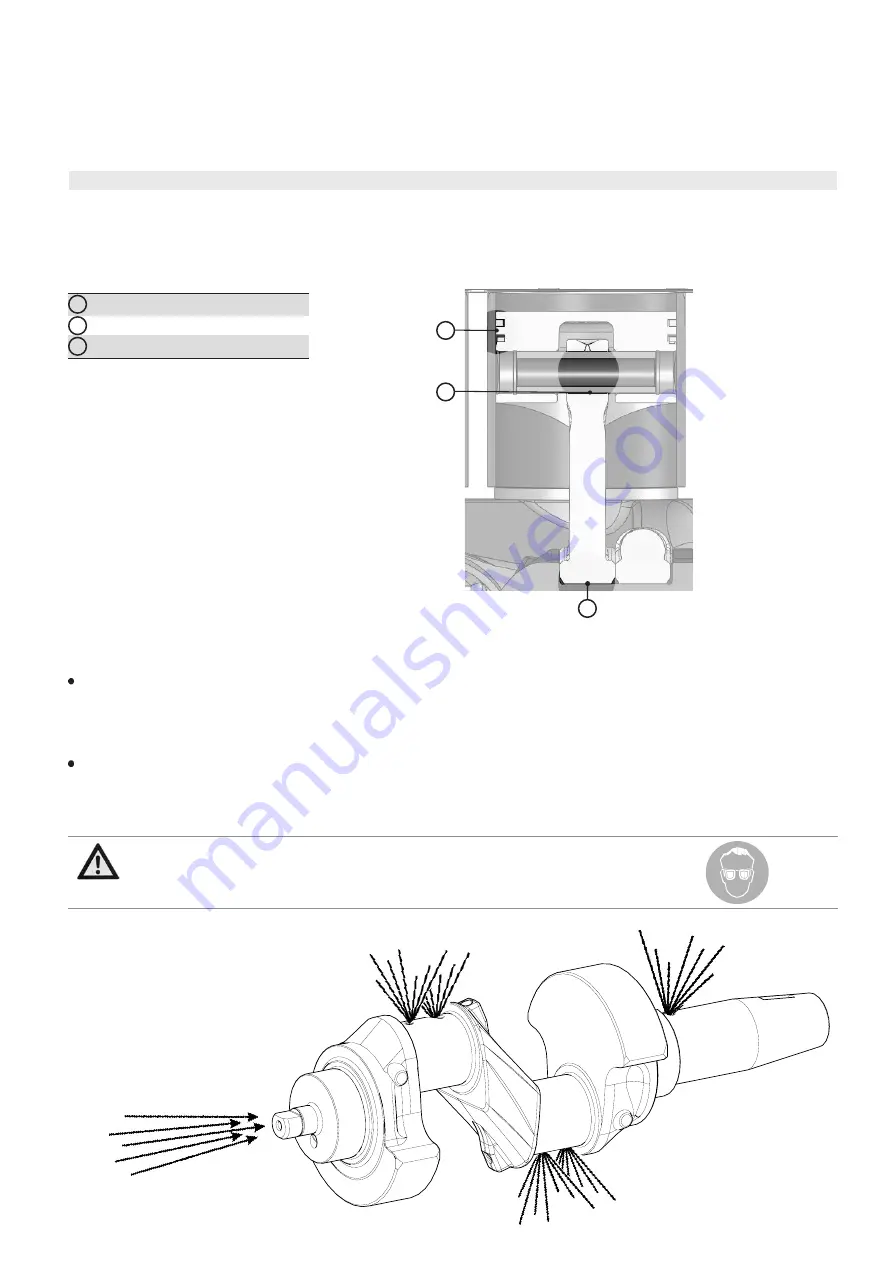

11 I Checking the compressor parts

Other components have to be examined according to the following criteria:

Cylinder liners

The cylinder liners should not have any visible damages in the piston movement area.

If there is fluting, the casing should be replaced.

Crankshaft

The bearing surfaces should not have any damages. The oil channels should be clean so that an

unhindered oil flow is ensured.

Piston - cylinder bore

0.13 mm

Connecting rod - piston pin 0.03 mm

Crankshaft - connecting rod 0.08 mm

Checking compressor parts for damages and wear

Before re-using removed compressor parts we recommend that they be checked for usability.

The wear limits listed below should be taken into consideration:

1

2

3

1

2

3

Clean the oil channels with compressed

air and check for passage

CAUTION

Remaining oil can cause eye injury!

When compressed air is used, remaining oil can splash out of the oil channels.

Wear protective goggles.

Compressed air