48

09665

-0

8.

20

18-

Gb

9

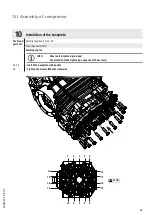

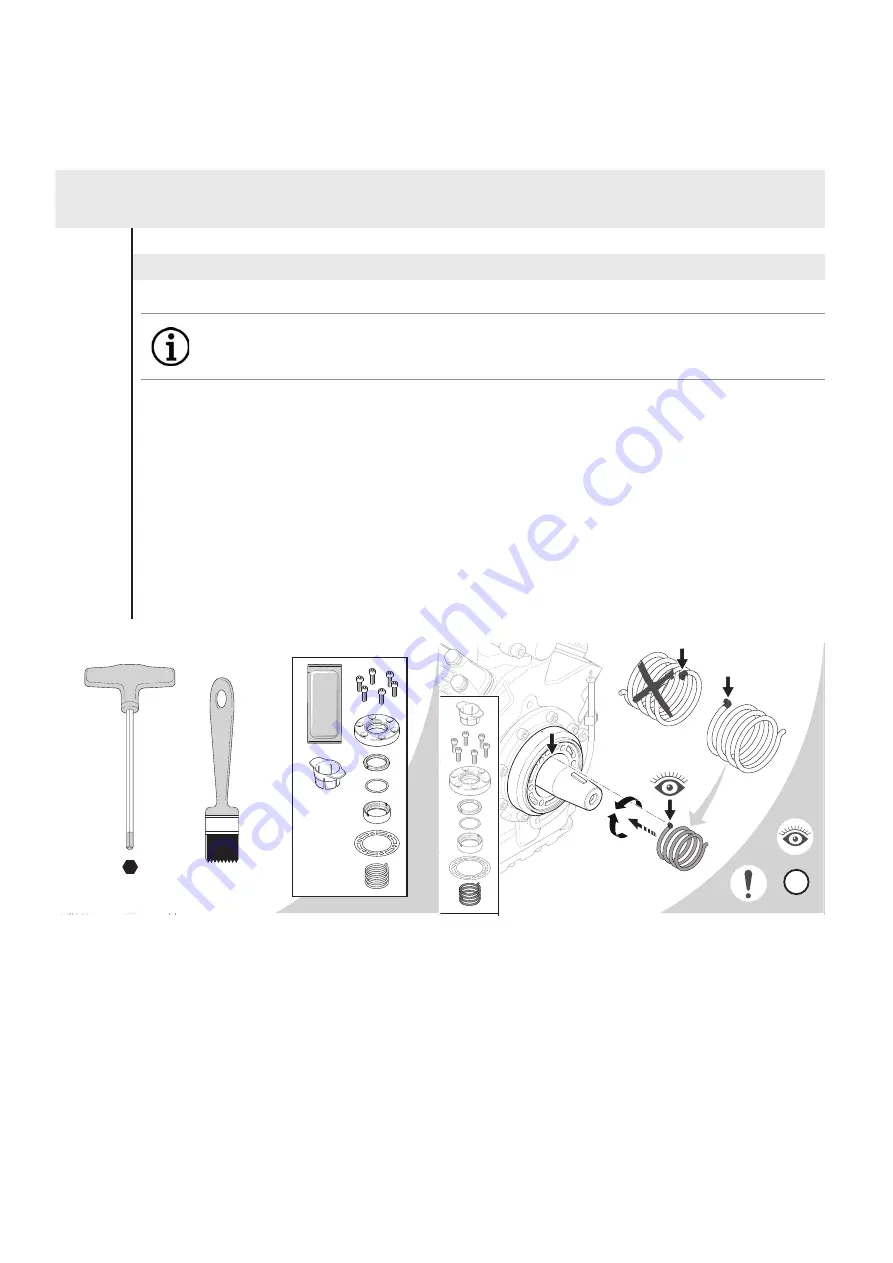

Fitting the shaft seal

Position in

parts list

Parts list position: 2010

Tools: Allen key 6 mm, brush

Working course

880

750

2050

2110

- Push the compression spring onto the crankshaft. Rotate the spring until the driving catch is engaged in the

crankshaft.

- Lubricate O-ring seating area in guide ring and O-ring with silicone grease.

- Push the guide ring with O-ring and sliding ring onto the crankshaft. Chamfer on sliding ring points outward.

Rotate all parts until the spring is engaged in the guide ring. Avoid scratches on the sliding ring!

- Apply silicone grease to rotary shaft seal in shaft seal cover.

- Install the shaft seal cover with the gasket using the protective sleeve. The inscription „TOP“ must be at the top.

- Press the shaft seal cover onto the bearing flange and tighten the screws.

- Turn the crankshaft by hand. Remove the protective sleeve.

- Install the leak oil collection device (only up to type code 014 and see also under service-kits:

clamping ring with oil felt).

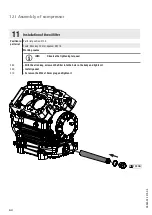

12 I Assembly of compressor

INFO

Caution! Avoid damages! Pay attention to the markings!

Be sure to observe the detailed working steps illustrated below!

Observe tightening torques!

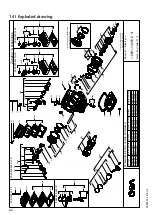

GEA Bock GmbH

Benzstraße 7, 72636 Frickenhausen, Germany

Phone: +49 7022 9454-0, Fax: +49 7022 9454-137

info@gea.com, www.gea.com

96445-01.2017-Gb

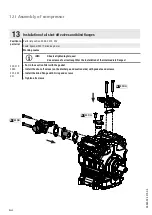

6 mm

POE

TOP

FK

TOP

TOP

1

2

3

4

5

6 mm

TOP

GEA Bock GmbH

Benzstraße 7, 72636 Frickenhausen, Germany

Phone: +49 7022 9454-0, Fax: +49 7022 9454-137

info@gea.com, www.gea.com

96445-01.2017-Gb

6 mm

POE

TOP

FK

TOP

TOP

1

2

3

4

5

6 mm

TOP

1