55

09665

-0

8.

20

18-

Gb

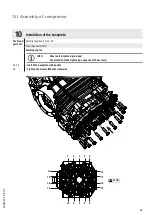

12 I Assembly of compressor

Torques for screwed connections

ATTENTION Take the reminders for commissioning in the assembly instruction for FK40 into account!

Designation

Screw size

Tightening torque

Shaft seal cover

M8

34 Nm

Connecting rod screws

M6

15 Nm

Oil drain plug

M22x1.5

1)

100 Nm

Oil intake plug

1/4“ NPTF

25 Nm

Sight glass

1 1/8“-18 NPTF

25 Nm

Flange connection

M10

60 Nm

Soldering gland-shut-off valves

Screw plugs

1/8“ NPTF

25 Nm

Plug

Electromagnetic coupling

M12

85 Nm

Decompression valve

M24

100 Nm

1)

= Screw with aluminium sealing ring

Screw size

Tightening torque

M8

34 Nm

M10

60 Nm

Special connections

General connections

with flat seal in fibre or metal design

Note:

Tighten the screws cross-wise in at least two stages

(tightening torque 50 / 100%) .

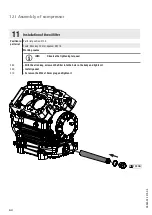

Working course

1. Evacuation / leak check of compressor

Connect the discharge and suction sides of the compressor to a vacuum pump

Evacuate the compressor from both sides; vacuum < 1.5 mbar. Check increase in pressure

In case there is an increase in pressure, check the compressor for leaks and evacuate again

Fill in the stipulated amount of oil (2.0 litres)

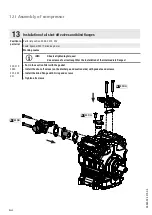

2. Carrying out the function test

Install the compressor in the system

Carry out a leak test with refrigerant

Make a test run. During this, check the oil level, the leak-tightness of the compressor, the running noise, pressure, temperatures and

the functioning of additional devices such as the capacity regulation

Remark:

If the compressor is going to remain in the warehouse, charge it with nitrogen (at about 3 bar pressure) for protection.

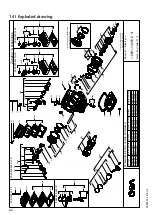

Checking the compressor