Maintenance

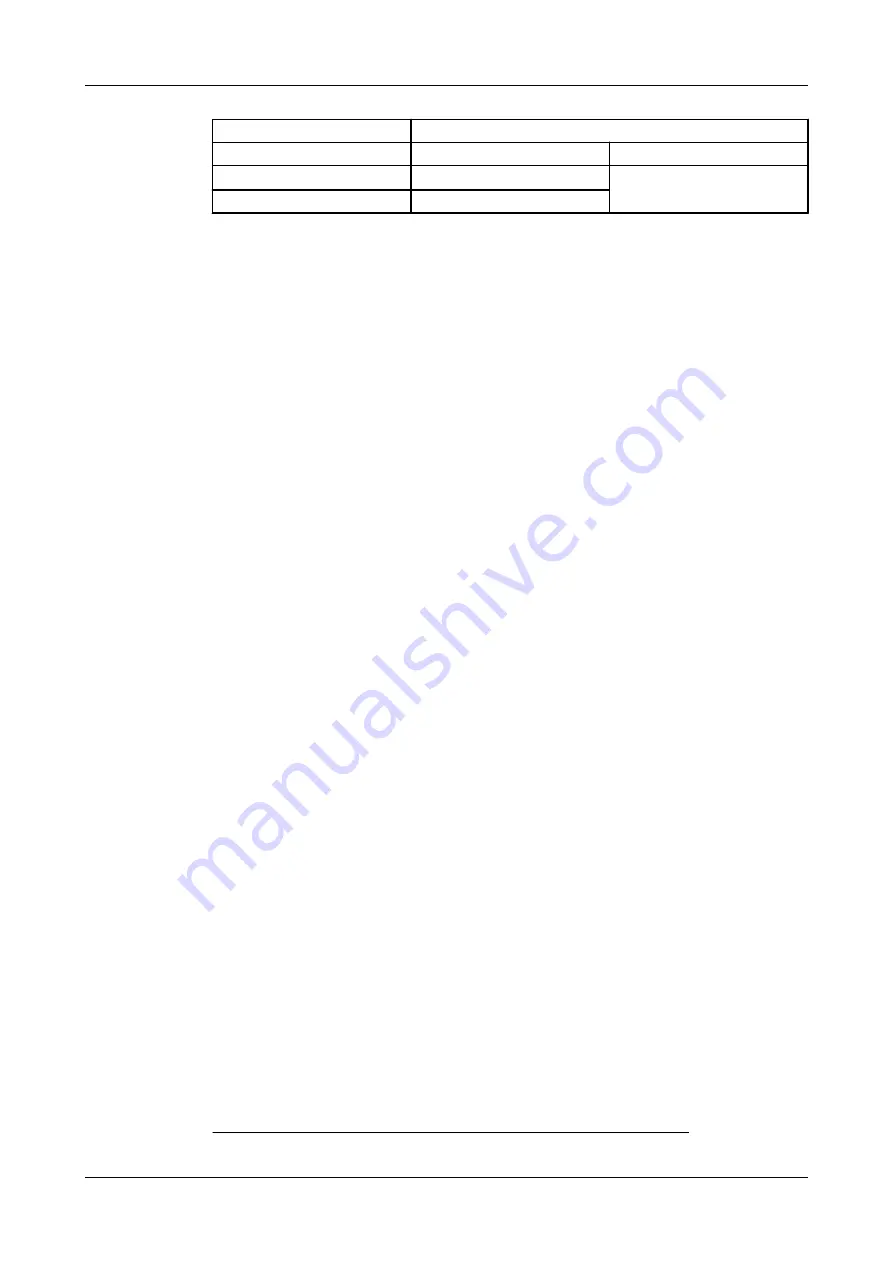

Number of operating hours

100

> 100

Oil analysis

8

X

Inspection leakage shaft seal

X

3.4

SERVICE MAINTENANCE SCHEDULE

General

The following maintenance has to be distinguished:

1.

Grasso Maintenance Monitor (GMM) or GEA Omni™

controller is

applied:

Maintenance A, B and C, service intervals are determined on measured

values of GMM/GEA Omni™. Maintenance B can vary between 7.500 and

18.000 running hours where 15.000 running hours is the standard for B-

maintenance for compressors running at To -10°C / Tc +35°C and 1200 min

-1

.

Maintenance to execute shown by the Omni or GMM

2.

GMM/GEA Omni™

is not applied:

Service intervals according to Service and Maintenance Schedules (SMS)

table based on fixed number of operating hours for A, B and C maintenance,

where 12.000 running hours is the standard for B-maintenance for

compressors running at To -10°C / Tc +35°C and 1200 min

-1

.

When running mainly at 1500 min

-1

speed the B maintenance interval

becomes 10.000 running hours fixed.

Maintenance to execute to be monitored and registered by the operator

3.4.1

Description Maintenance A, B and C

General

The following maintenance has to be distinguished;

1.

Small maintenance, Maintenance A, Yearly inspection, or every 5000 running

hours at 1500 rpm or every 6000 hours at 1200 rpm, whatever comes first

2.

Medium maintenance, Maintenance B

3.

Large maintenance, Maintenance C

Maintenance routine sequence:

1.

A-maintenance, yearly or every 5000 running hrs at 1500 rpm or every 6000

hrs at 1200 rpm in between of different B- and C routines

2.

2x B-maintenance

3.

C Maintenance

As programmed: A – B – A – B – A – C

When GMM or Omni™ is applied: Follow up A, B or C when shown by the

monitor

8

Consult your oil supplier.

MAINTENANCE

SERVICE MAINTENANCE SCHEDULE

0089288_imm_v_english_19

07.04.2021

43