4

APPENDIX; Product Information (PI)

4.1

GRASSO MAINTENANCE MONITOR

Hint!

In case the GEA Omni™ is included, the GMM hardware is not

required, since the GEA Omni™ includes the GMM software.

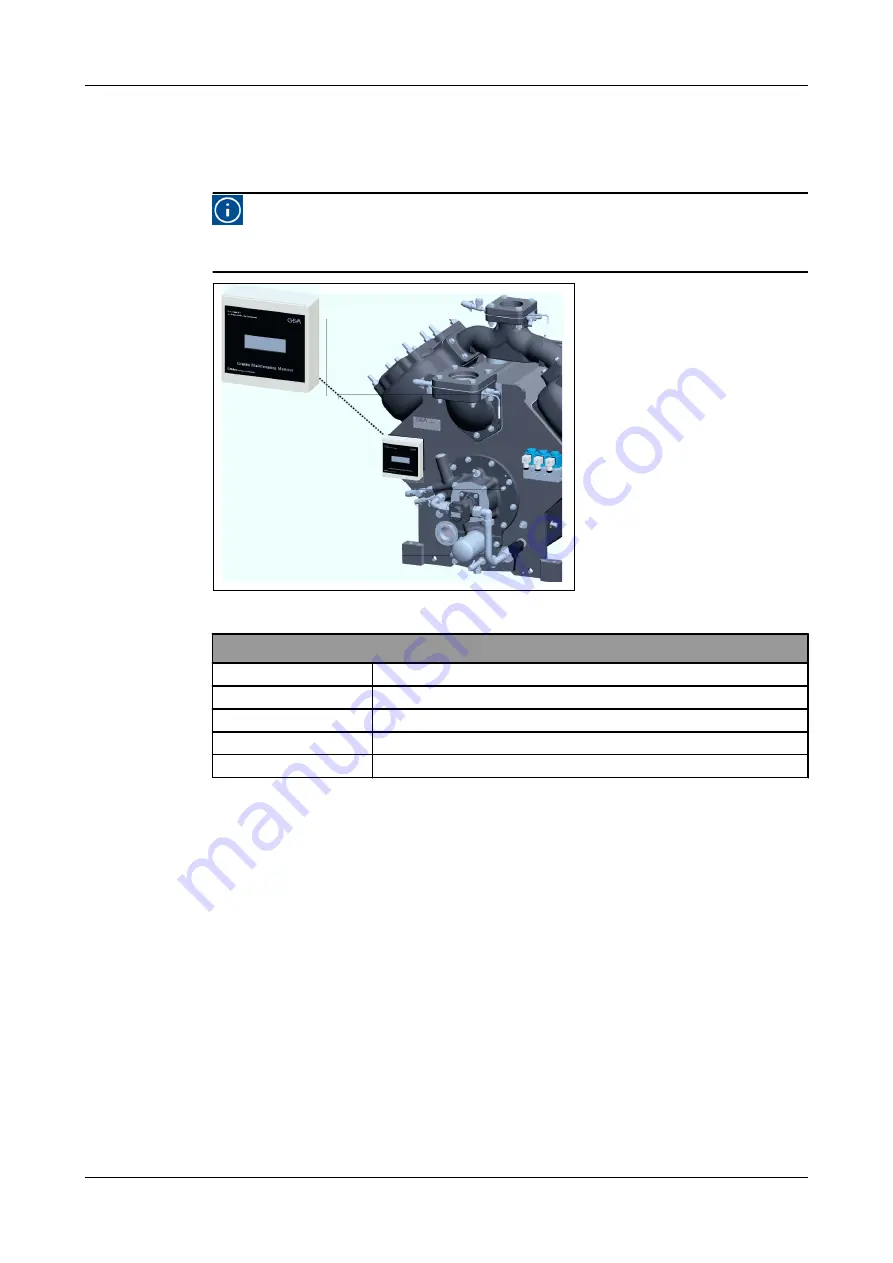

Fig.16:

Grasso Maintenance Monitor

GMM connections

1

Ethernet

2

Power input (10 .. 30 VDC)

3

Compressor speed sensor

4

Discharge temperature sensor

5

Oil temperature sensor

This micro processor controlled maintenance monitor is a unique standalone

device for flexible maintenance. This equipment strongly recommended to fit on V

series compressors to be able to tune the maintenance to the actual running

conditions. In other words: “On time maintenance”

This results in (nearly) all cases in longer service intervals and significantly less

maintenance costs. For industrial refrigeration compressors this is a unique

development. To maintain the highest level of reliability, even with extended

service intervals, this series is fitted with the best possible components available.

Besides this practical instrument Grasso is able to make, in advance, an

analyses based on a theoretical profile of the compressor and the running

conditions. In this way an indication of the running costs ( Total Costs of

Ownership, TCO) can be produced.

4.2

GENERAL LIMITS OF OPERATION GRASSO V

When operating the compressor, none of the limits of operation as stated in the

table below must be exceeded. *

10

APPENDIX; Product Information (PI)

GRASSO MAINTENANCE MONITOR

0089288_imm_v_english_19

07.04.2021

51