PRODUCT INFORMATION

LIQUID CHILLER GRASSO DX R

200 ... 1600

38

_601011_pi_dxr_gbr_1_.doc

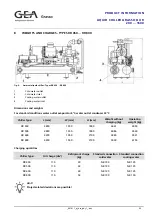

11 ABSORPTION

DEVICE

11.1 General Information

The operation of ammonia liquid chillers in refrigerating plants is subject to venting the machine room in

accordance with the Regulations on the Prevention of Accidents (VBG 20), § 12 and § 17.

In case of leakage, the machinery room air shall be let off to the outside in a non-hazardous manner.

Should this be impossible, the machinery room air shall be led through an absorption tank and to be resupplied to

the machinery room after cleaning.

For this case, Grasso has developed a series of ammonia absorption facilities the size of which depends upon the

quantity of refrigerant in the NH

3

liquid chillers and refrigerating plants.

If there are several liquid chillers, the absorption facility shall be selected with regard to the liquid chiller having

the largest filling weight.

If the maximum amount should be exceeded, a combination of several absorption facilities is possible.

The absorption facilities have been designed to be integrated into usual ventilation systems.

11.2 Functional description

The high-pressure ventilator is put into operation by an ammonia warning device if the maximum permissible

ammonia concentration of 50 ppm is exceeded.

It sucks the air-ammonia mixture off and forces it into the plastic vessel which is filled with water.

The amount of water in the plastic vessel is sufficient to absorb the total refrigerant charge, with the decrease in

solubility by warming-up being taken into account.

After leaving the gas distribution pipe the air bubbles through the water, and the ammonia is absorbed.

The cleaned air is recirculated to the machine room.

If the ammonia concentration falls below the threshold value, the ventilator is switched off.

After the operation of the absorber due to an increased ammonia concentration in the machine room, the

contaminated water must be disposed off in a workmanlike manner.

If the absorber is not operating over a longer period, exchange the water every three months to prevent rotting.

This occasion may be utilized to check the plant and clean the gas distrubtion pipe, if required.

Due to the design of the gas distribution pipe it is not recommended to add chemicals to the water charge to

neutralize the ammonia.

11.3 Installation

The absorber is placed on an even support.

Particular measures other than the selection of a frost-free location are not required.

The charging connection (unpressurized) may be integrated in an existing water system.

The electrical installation of the high-pressure ventilator and ammonia warning device shall be performed

according to the technical specification in such a way that its function is ensured even when the main switch of

the refrigerating plant is off.

The integration into venting systems should take place according to the local conditions and requirements.

If desired, the bleed line of the refrigerating plant may be connected to the absorber.

Summary of Contents for Grasso DX 600

Page 1: ..._601011_pi_dxr_gbr_1_ doc 1 Liquid Chiller Grasso DX R 200 1600 Product Information ...

Page 4: ......

Page 6: ......

Page 44: ......