The accessories of the compressor include those

devices and systems with which the efficient

operation of the compressor in the installation can

be promoted and checked and those which, in the

event of failures prevent the compressor from

being damaged.

The accessories should be distinguished as follows:

A) Accessories the use of which has been

prescribed by the compressor

manufacturer,among which:

•

Pressure gauges for suction pressure, discharge

pressure and oil pressure; in the case of two stage

compressors also for the intermediate pressure;

•

Pressure safety switches for discharge pressure

and lubricating oil pressure;

•

For two-stage compressors: Electrically operated ca-

pacity control (also to be used as run-in control with

which the compressor can proceed as favourably as

possible to two-stage compression during the time

the installation attains the operating conditions).

B) Accessories the use of which is deemed

necessary by the installation engineer,

amongwhich:

•

Suction pressure safety switch;

•

Cylinder head temperature safety device;

•

Crankcase heating;

•

For single-stage compressors: Manually or

electically operated capacity control.

The choice of the accessories depends on the type

of plant, the refrigerant used and the operating

conditions; therefore, this choice will be

determined by the installation engineer.

In this chapter only those accessories are described

that can be supplied by the manufacturer of the

compressor. If other accessories have been

provided by the installation engineer, their

description can be found in the plant manual.

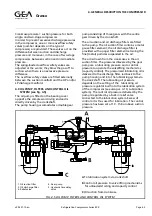

5.1 PRESSURE GAUGES

The pressure gauges necessary for checking the

correct operation of compresssor and installation

are mounted on a panel, each of them being

connected to the compressor via a shut-off valve.

For single-stage compressors three pressure

gauges have been provided, viz. a suction pressure

gauge, a discharge pressure gauge and an oil

pressure gauge; moreover, for two-stage

compressors, there still is an intermediate pressure

gauge.

The gauges indicate the pressure in bars; at a pressure

lower than the atmospheric, the pressure gauge

indicates a negative value. The scale of suction,

discharge and intermediate pressure gauges is

adjusted to the refrigerant in the plant, as besides the

pressure scale also the saturation temperatures

corresponding to te overpressures are given.

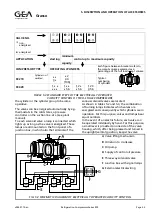

5.2 PRESSURE SAFETY SWITCHES

In order to protect compressor and plant, safety

switches for discharge pressure, suction pressure

and lubricating oil pressure are provided. They are

mounted on a panel and connected to the

pressure connections of the compressor via the

pressure gauge valves. The switch contacts are

incorporated in the control current circuit for the

drive motor of the compressor.

The discharge pressure safety switch

(Danfoss

pressure control type RT 5 for halocarbon

refrigerants, type RT 5A for NH

3

) protects the

compressor against excessive discharge pressure.

In case the preset pressure is exceeded, the

control current circuit is interrupted and the

compressor stops.

The suction pressure safety switch

(Danfoss

pressure control type RT 1 for R12, R22, etc. type

RT 1A for NH

3

) protects compressor and plant

against too low suction pressure. In case the

pressure drops below the preset value, the

compressor is switched off.

The switching pressure of both switches can be

adjusted by turning the main spindle after

removing a cap on the top side of the housing.

The adjustment can be read on a scale behind the

window in the front cover. Between the cut-out

pressure and the pressure at which the switch

makes circuit again, there is a fixed difference of

approx. 0.4 bar in the suction pressure safety

switch and of approx. 1 bar in the discharge

pressure safety switch.

Both pressure safety switches are provided with a

locking device when cut out, so that, on return of

the original pressures, the compressor does not

become operative automatically again. The

switches can be unlocked by pushing a green

button on the side; however, this may be done

only after the cause of the switching off of the

compressor has been investigated and the failure

has been remedied. In both switches an auxiliary

contact is provided for connection a pilot lamp or

a klaxon.

Refrigeration Division

Grasso

5. DISCRIPTION AND OPERATION OF ACCESSORIES

v002.97.10.en

Refrigeration Compressors Series RC9

Page 5.1